Good track is paramount for enjoying model railroading. Few things influence your layout’s reliability and your overall experience more than well-laid track. This guide, “A Beginner’s Guide to Model Building Part 4,” provides essential knowledge and tips to achieve smooth, dependable trackwork.

Choosing the Right Rail Metal: Nickel Silver

The best and only choice for model railroad track is nickel silver.

While brass and steel were historically used, these metals suffer from poor electrical conductivity due to oxidation, requiring frequent cleaning. Brass also has an unrealistic yellowish tint. Nickel silver, on the other hand, boasts superior electrical conductivity and a more realistic silver appearance, closely resembling the prototype.

To enhance realism, weathering techniques can diminish the shiny appearance on the sides of nickel silver rails. (Refer to Part 10 of this guide for weathering tips).

Selecting the Appropriate Track Type

Beginners should focus on these three primary track types:

- Sectional

- Sectional with integrated roadbed

- Flex track

Hand-laid track, while visually stunning, is best left for experienced modelers.

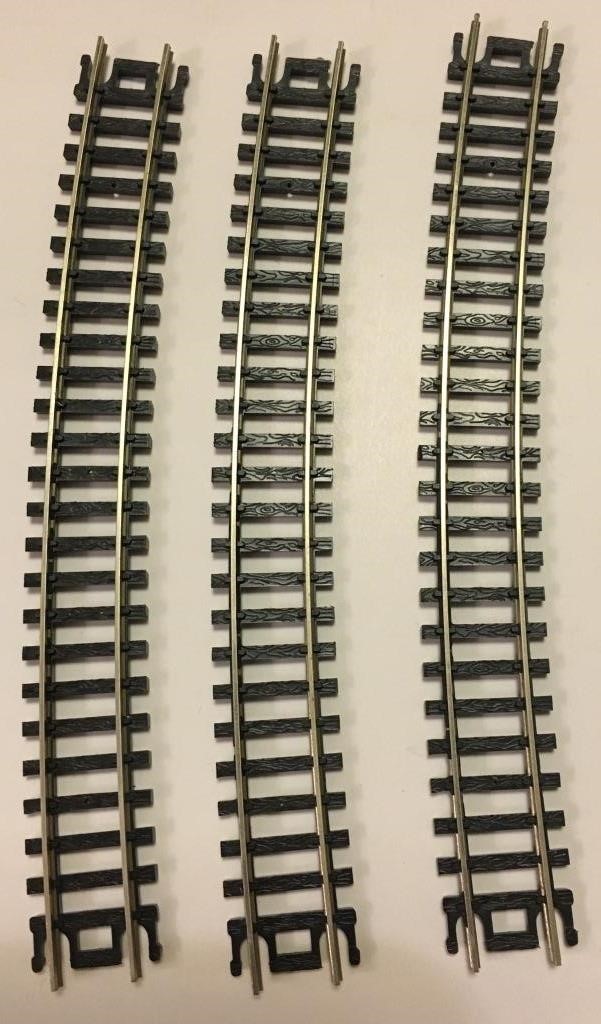

Sectional Track

Sectional track consists of fixed-length straight and curved sections with black plastic ties and firmly embedded rails. These tracks easily connect together to build a model railway quickly.

Various lengths of straight track and radii of curved track are available for creating specific layouts. Turnouts (switches) are also available, generally with continuously curving diverging routes using the smallest radius. Prototype turnouts, by contrast, have straight diverging routes beyond the frog.

Sectional track excels when following published track plans, ensuring smooth joints throughout the layout. Careful planning is crucial when designing your own layout to avoid kinks at track joints. Track-planning software can assist in ensuring smooth connections. When assembling, ensure both rails slide into, not on top of, each rail joiner. Replace loose rail joiners to prevent derailments and ensure reliable electrical flow.

Sectional Track with Integrated Roadbed

Integrated roadbed sectional track has surpassed traditional sectional track in many train sets due to its more realistic appearance and secure connections.

Integrated roadbeds reduce misalignment and improve electrical continuity. They also provide a degree of protection against dirt and debris, which is especially beneficial when setting up layouts on the floor.

However, track systems from different manufacturers may not be compatible, even if their conventional sectional track worked together previously. Ensure the rail is firmly held in the rail joiner to prevent misalignment.

Flex Track

Flex track offers flexibility, allowing for custom curves and track arrangements. It comes in lengths of approximately two to four feet, depending on the scale. Two main types exist: track with gaps under one rail (allowing it to slide) and track with alternating gaps under each rail.

The more flexible type, with all gaps under one rail, is easier for beginners.

Flex track provides several benefits over sectional track:

- Create any desired radius and start/stop curves at any point.

- Implement easements into and out of curves for enhanced realism and smoother operation. Easements reduce misalignment between body-mounted couplers.

- Fewer rail joints result in fewer mechanical and electrical issues.

Essential tips for using flex track:

-

Use a good pair of flush-cutters (e.g., Xuron “Track Cutter”) to cut rail.

-

Trim ties at rail joints to make room for rail joiners.

-

File the end of the rail smooth and slightly tapered after cutting.

-

Position the “sliding” rail on the inside of curves.

-

Solder two lengths of flex track together before bending for long curves.

Flex track is compatible with realistic turnouts featuring “numbered frogs” (e.g., #4, #6, or #8), indicating the angle of divergence.

- #4 turnouts: tight industrial areas, smaller locomotives and cars.

- #6 turnouts: yards and branch lines, medium-sized locomotives and cars.

- #8 turnouts: mainline trains, large locomotives and full-length cars.

Recommended brands include Walthers and Atlas Custom Line (avoid Atlas “Snap Track”). Peco turnouts are also excellent, mechanically precise, and DCC-friendly.

Power-routing turnouts simplify powering stub-end sidings on DC layouts.

Peco turnouts with numbered frogs have realistically straight diverging routes.

Other respectable brands include Micro Engineering, Shinohara, and Fast Tracks.

Close-up of Atlas Custom Line #4 turnout

Avoiding S-Curves

S-curves (opposing curves connected directly) cause derailments, especially with body-mounted couplers.

Tips to avoid S-curves:

- Use a straight track section between opposing curves (at least 1.5 times the length of your longest car).

- Incorporate easements.

- Use turnouts with numbered frogs.

- Pay attention to hidden S-curves (crossovers, siding entrances).

Understanding Track “Code”

“Code” refers to the height of the rail in thousandths of an inch (e.g., code 100 = 0.100″).

While common train set codes (code 100 for HO, code 80 for N) are usable, smaller, more realistic-looking codes (code 83 in HO, code 55 in N) are preferred.

Rail Joiners: Electrical and Mechanical Connection

Metal rail joiners provide mechanical and electrical connections between track sections. Ensure compatibility with your rail code. Plastic, insulated rail joiners are also available.

Insulated rail joiners are useful for:

- Avoiding short circuits with turnouts with all-metal frogs.

- Avoiding short circuits at wyes or reversing loops.

- Dividing DC layouts into multiple blocks.

- Dividing large DCC layouts into power districts.

Use new rail joiners, ensure proper rail insertion, and confirm a snug fit.

Roadbed: Sound Dampening and Realism

Roadbed is a soft material laid beneath track, enhancing realism and reducing noise.

Three primary materials are used: cork, foam, and Homasote.

Cork: Cork roadbed comes in strips with pre-cut bevels. Stagger joints and lightly sand after securing.

Foam: Foam roadbed is a newer option, available in various forms, like Woodland Scenics’ “Track-Bed.”

Homasote: Homasote is a pressed-paper board with excellent sound deadening and spike-holding properties. It requires cutting into strips and sealing with paint.

Fastening Track Down: Securing the Rails

Prototype track relies on its weight and ballast for stability. Model track requires mechanical assistance.

Two main methods: track nails and adhesives.

Track Nails: Many track brands have pre-drilled holes for track nails (spikes). Homasote excels at holding track nails. When using foam or cork, ensure nails reach the sub-roadbed. Avoid over-tightening.

Adhesives: Gluing track down provides a cleaner appearance but makes changes more difficult. Use adhesives compatible with plastic ties. Foam-safe adhesives are crucial when using foam insulation boards.

Controlling Turnout (Switch) Points

The points are the moving blades that direct trains through a turnout.

Some turnouts have built-in springs to hold the points in position. Others (e.g., Walthers, Atlas Custom Line) require additional mechanisms.

Solutions:

- Ground throws (e.g., Caboose Industries). Choose models with internal springs.

- Electric slide-switch linkage.

- Cable linkage to under-layout devices (e.g., “Blue Point,” “BullFrog”).

- Slow-motion “stall-motor” electric switch machines (e.g., “Tortoise”).

Conclusion: Smooth, Reliable Trackwork

Good track is essential for a satisfying model railroading experience. With the information and tips outlined in this “Beginner’s Guide to Model Building Part 4,” you can confidently select and install trackwork that provides years of reliable and enjoyable operation.