Electromagnetic compatibility (EMC) engineering is crucial for ensuring the safe and reliable operation of electronic systems. CONDUCT.EDU.VN offers a practical guide that provides comprehensive strategies for minimizing electromagnetic interference and ensuring functional safety. This guide is essential for professionals seeking to understand EMC principles, improve design practices, and mitigate risks associated with electromagnetic disturbances.

1. Understanding EMC Engineering Fundamentals

EMC engineering focuses on ensuring that electronic devices can operate in their intended electromagnetic environment without causing interference to other devices or being susceptible to interference themselves. The principles of EMC are essential in various industries, including aerospace, automotive, medical, and telecommunications, where the reliable operation of electronic systems is paramount.

1.1. The Importance of EMC

Electromagnetic compatibility is important for several reasons:

- Safety: Electromagnetic interference (EMI) can cause malfunctions in safety-critical systems, leading to hazardous situations.

- Reliability: EMI can degrade the performance and lifespan of electronic devices.

- Compliance: Regulatory standards, such as those set by the Federal Communications Commission (FCC) in the United States and the European Union’s EMC Directive, mandate that electronic devices meet specific EMC requirements.

- Performance: Ensuring EMC can improve the overall performance and efficiency of electronic systems.

1.2. Key Concepts in EMC

Several key concepts are fundamental to understanding EMC:

- Electromagnetic Interference (EMI): Any unwanted electromagnetic energy that disrupts the operation of electronic devices.

- Electromagnetic Susceptibility (EMS): The vulnerability of a device to EMI.

- Emissions: Electromagnetic energy intentionally or unintentionally generated by a device.

- Immunity: The ability of a device to function correctly in the presence of EMI.

- Shielding: The use of conductive barriers to block electromagnetic fields.

- Grounding: The establishment of a common reference point for electrical circuits to minimize voltage differences and reduce noise.

- Filtering: The use of electronic components to block or attenuate unwanted frequencies.

Electromagnetic Compatibility Principles

Electromagnetic Compatibility Principles

2. The EMC Engineering Design Process

Designing for EMC involves integrating EMC considerations into every stage of the product development lifecycle, from initial concept to final testing. This proactive approach helps to minimize the risk of EMC-related problems and ensures compliance with regulatory requirements.

2.1. Planning and Requirements Definition

The first step in the EMC design process is to define the EMC requirements for the product. This includes identifying the relevant regulatory standards, the expected electromagnetic environment, and the acceptable levels of emissions and immunity.

Checklist for Planning and Requirements Definition:

- Identify applicable EMC standards (e.g., FCC, CISPR, IEC).

- Define the product’s intended electromagnetic environment.

- Specify acceptable emission limits.

- Specify required immunity levels.

- Document all requirements in a clear and concise manner.

2.2. Circuit and PCB Design

The design of electronic circuits and printed circuit boards (PCBs) plays a crucial role in EMC performance. Good circuit and PCB design practices can minimize emissions and improve immunity.

Best Practices for Circuit and PCB Design:

- Minimize Loop Areas: Keep current loops as small as possible to reduce radiated emissions.

- Use Ground Planes: Utilize ground planes to provide a low-impedance return path for currents and reduce ground bounce.

- Proper Component Placement: Place critical components close together to minimize trace lengths and reduce signal reflections.

- Decoupling Capacitors: Use decoupling capacitors to provide a local source of energy for integrated circuits and reduce noise on power lines.

- Signal Routing: Route high-speed signals away from the edges of the PCB and use controlled impedance traces to minimize reflections.

- Layer Stack-Up: Optimize the PCB layer stack-up to provide good signal integrity and minimize crosstalk.

2.3. Shielding Techniques

Shielding is an effective method for reducing emissions and improving immunity. It involves enclosing electronic circuits in conductive enclosures or applying conductive coatings to block electromagnetic fields.

Types of Shielding Techniques:

- Enclosures: Use metal enclosures to provide a barrier against electromagnetic fields. Ensure that enclosures are properly sealed to prevent leakage of emissions.

- Conductive Gaskets: Use conductive gaskets to create a tight seal between enclosure parts and prevent EMI leakage.

- Shielded Cables: Use shielded cables to prevent emissions from cable conductors and protect signals from external interference.

- Conductive Coatings: Apply conductive coatings to plastic enclosures to provide shielding.

2.4. Grounding Strategies

Effective grounding is essential for minimizing noise and ensuring EMC. Proper grounding techniques provide a low-impedance path for return currents and reduce the potential for ground loops.

Grounding Best Practices:

- Single-Point Grounding: Use a single-point grounding system to avoid ground loops and minimize noise.

- Ground Planes: Utilize ground planes to provide a low-impedance return path for currents.

- Star Grounding: Use a star grounding configuration to connect all ground points to a central ground point.

- Chassis Grounding: Ground the chassis of electronic equipment to provide a safe and effective path for fault currents.

2.5. Filtering Techniques

Filtering is used to attenuate unwanted frequencies and reduce emissions. Filters can be implemented using discrete components, such as capacitors, inductors, and resistors, or integrated into electronic circuits.

Types of Filters:

- Low-Pass Filters: Attenuate high-frequency signals while allowing low-frequency signals to pass.

- High-Pass Filters: Attenuate low-frequency signals while allowing high-frequency signals to pass.

- Band-Pass Filters: Allow signals within a specific frequency range to pass while attenuating signals outside that range.

- Band-Stop Filters: Attenuate signals within a specific frequency range while allowing signals outside that range to pass.

2.6. Cable Management

Cables can act as antennas, radiating emissions and conducting interference. Proper cable management techniques can minimize these effects.

Cable Management Best Practices:

- Shielded Cables: Use shielded cables to reduce emissions and improve immunity.

- Cable Routing: Route cables away from sensitive circuits and components.

- Cable Length: Minimize cable lengths to reduce emissions and signal degradation.

- Cable Termination: Properly terminate cables to minimize reflections and ensure good signal integrity.

- Ferrite Beads: Use ferrite beads to attenuate high-frequency noise on cables.

3. EMC Testing and Compliance

EMC testing is essential for verifying that electronic devices meet the required emission and immunity levels. Compliance with EMC standards is often required for regulatory approval and market access.

3.1. Types of EMC Tests

Several types of EMC tests are commonly performed:

- Emissions Tests: Measure the electromagnetic energy radiated or conducted by a device.

- Immunity Tests: Assess the ability of a device to function correctly in the presence of electromagnetic disturbances.

- Conducted Emissions Tests: Measure the electromagnetic energy conducted along power and signal cables.

- Radiated Emissions Tests: Measure the electromagnetic energy radiated from a device.

- Electrostatic Discharge (ESD) Tests: Simulate the effects of electrostatic discharge on a device.

- Radiated Immunity Tests: Assess the ability of a device to function correctly when exposed to radiated electromagnetic fields.

- Electrical Fast Transient (EFT) Tests: Simulate the effects of fast transient disturbances on a device.

- Surge Tests: Simulate the effects of high-energy surges on a device.

3.2. EMC Test Standards

Various EMC test standards are used worldwide, including:

- FCC Part 15 (United States): Regulates the emission of electromagnetic energy from electronic devices.

- CISPR Standards (International): Standards developed by the International Special Committee on Radio Interference for measuring and limiting electromagnetic emissions.

- IEC Standards (International): Standards developed by the International Electrotechnical Commission for EMC testing and requirements.

- EN Standards (Europe): European Norm standards harmonized under the EMC Directive.

3.3. Setting Up an EMC Test Facility

Setting up an EMC test facility requires careful planning and investment in specialized equipment. Key considerations include:

- Shielded Room: A shielded room is essential for minimizing external interference during EMC testing.

- Test Equipment: EMC test equipment includes spectrum analyzers, signal generators, amplifiers, antennas, and conducted emissions test equipment.

- Calibration: All test equipment must be regularly calibrated to ensure accurate measurements.

- Test Plan: A detailed test plan should be developed to ensure that all required tests are performed in a consistent and repeatable manner.

3.4. Performing EMC Tests

Performing EMC tests requires careful attention to detail and adherence to the relevant test standards. Key steps include:

- Setup: Properly set up the device under test (DUT) and test equipment according to the test standard.

- Calibration: Calibrate the test equipment before performing the tests.

- Measurement: Perform the required measurements and record the results.

- Analysis: Analyze the test results to determine whether the DUT meets the required emission and immunity levels.

- Reporting: Prepare a detailed test report documenting the test setup, procedures, and results.

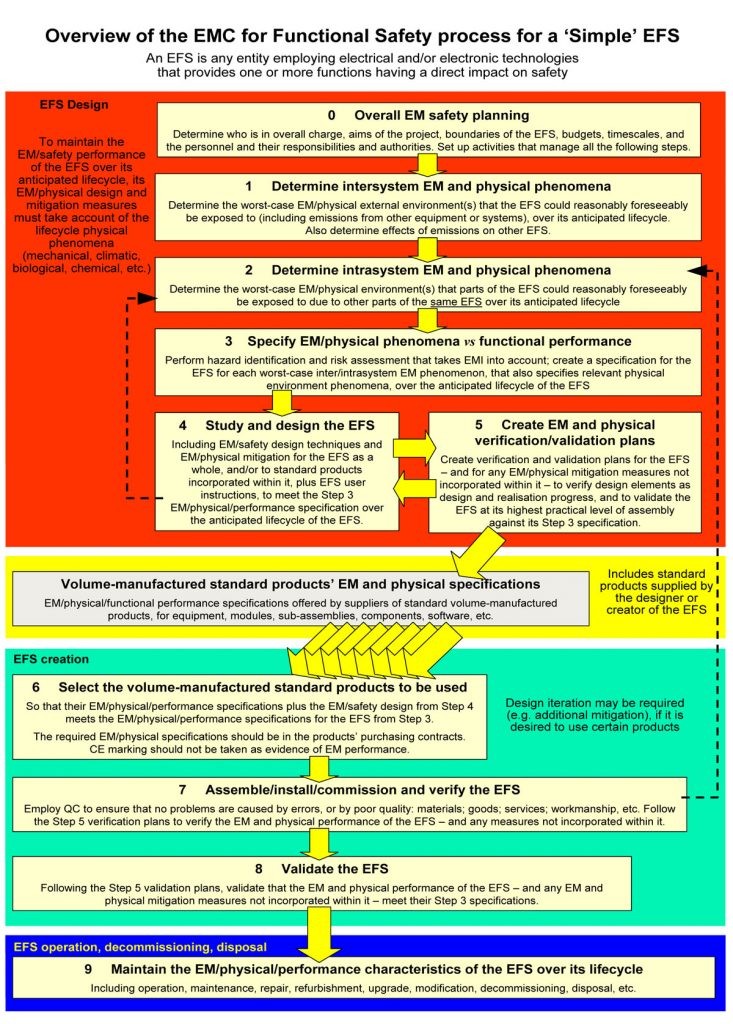

4. EMC for Functional Safety

EMC for functional safety is a critical aspect of ensuring the safe operation of electronic systems in safety-related applications. Functional safety standards, such as IEC 61508, require that EMC risks be addressed as part of the overall safety lifecycle.

4.1. The Role of EMC in Functional Safety

Electromagnetic interference can cause malfunctions in safety-critical systems, leading to hazardous situations. EMC for functional safety aims to minimize these risks by ensuring that electronic systems are designed to be robust against EMI and that potential failure modes are identified and mitigated.

4.2. Risk Assessment

Risk assessment is a key component of EMC for functional safety. It involves identifying potential hazards, assessing the likelihood and severity of those hazards, and implementing measures to reduce the associated risks.

Steps in Risk Assessment:

- Identify Hazards: Identify potential sources of EMI and the potential effects on the system.

- Assess Risks: Evaluate the likelihood and severity of each hazard.

- Implement Mitigation Measures: Implement design and testing measures to reduce the risks to an acceptable level.

- Verify and Validate: Verify that the mitigation measures are effective and validate that the system meets the required safety levels.

4.3. Mitigation Strategies

Various mitigation strategies can be used to reduce EMC risks in safety-related systems:

- Shielding: Use shielding to protect sensitive circuits from EMI.

- Filtering: Use filters to attenuate unwanted frequencies.

- Redundancy: Implement redundant systems to provide backup in case of failure.

- Diversity: Use diverse technologies to reduce the likelihood of common-mode failures.

- Monitoring: Monitor system performance to detect potential problems early.

4.4. Standards and Guidelines

Several standards and guidelines provide guidance on EMC for functional safety:

- IEC 61508: The basic standard for functional safety of electrical, electronic, and programmable electronic safety-related systems.

- IEC 61000-1-2: Provides a methodology for achieving functional safety with regard to electromagnetic phenomena.

- ISO 26262: The automotive functional safety standard.

- ISO 14971: The medical device risk management standard.

5. Advanced EMC Engineering Techniques

Advanced EMC engineering techniques are used to address complex EMC challenges and improve the performance of electronic systems. These techniques include modeling and simulation, near-field scanning, and advanced shielding materials.

5.1. Modeling and Simulation

Modeling and simulation tools can be used to predict the EMC performance of electronic systems and identify potential problems early in the design process. These tools can simulate electromagnetic fields, signal integrity, and power distribution, allowing engineers to optimize designs for EMC.

Types of Modeling and Simulation Tools:

- Finite Element Method (FEM) Solvers: Used to simulate electromagnetic fields in complex structures.

- Time-Domain Reflectometry (TDR) Simulators: Used to analyze signal integrity and impedance matching.

- Power Distribution Network (PDN) Simulators: Used to analyze power distribution and identify potential noise problems.

5.2. Near-Field Scanning

Near-field scanning is a technique used to measure electromagnetic fields close to a device. This technique can be used to identify sources of emissions and assess the effectiveness of shielding and filtering measures.

Applications of Near-Field Scanning:

- Identify Sources of Emissions: Locate areas of high electromagnetic field strength.

- Evaluate Shielding Effectiveness: Measure the reduction in electromagnetic field strength provided by shielding materials.

- Optimize Filter Performance: Evaluate the performance of filters in reducing emissions.

5.3. Advanced Shielding Materials

Advanced shielding materials are used to provide high levels of shielding effectiveness in demanding applications. These materials include conductive fabrics, metal foams, and nanocomposites.

Types of Advanced Shielding Materials:

- Conductive Fabrics: Fabrics coated with conductive materials to provide shielding.

- Metal Foams: Lightweight materials with high shielding effectiveness.

- Nanocomposites: Materials with nanoparticles embedded in a matrix to provide enhanced shielding properties.

6. Regulatory Compliance and Standards

Adhering to regulatory compliance and standards is a critical aspect of EMC engineering. Compliance ensures that electronic devices meet specific emission and immunity requirements, facilitating market access and preventing potential legal issues.

6.1. Key Regulatory Bodies

Several key regulatory bodies oversee EMC standards globally:

- Federal Communications Commission (FCC): In the United States, the FCC regulates interstate and international communications, including setting limits on electromagnetic emissions from electronic devices.

- Website: https://www.fcc.gov/

- European Union (EU): The EU enforces EMC Directive 2014/30/EU, which requires that products sold within the European Economic Area meet specific EMC standards.

- International Electrotechnical Commission (IEC): The IEC develops international standards for electrical and electronic technologies, including EMC.

- Website: https://www.iec.ch/

- International Special Committee on Radio Interference (CISPR): CISPR sets international standards for radio disturbance characteristics.

- Website: (Part of IEC)

6.2. Important EMC Standards

Some of the most important EMC standards include:

- FCC Part 15: Regulations for radio frequency devices, covering unintentional and intentional radiators.

- CISPR 11: Industrial, scientific, and medical (ISM) equipment – Radio-frequency disturbance characteristics – Limits and methods of measurement.

- CISPR 22: Information technology equipment – Radio disturbance characteristics – Limits and methods of measurement. (Replaced by CISPR 32)

- CISPR 25: Vehicles, boats, and internal combustion engines – Radio disturbance characteristics – Limits and methods of measurement for the protection of on-board receivers.

- IEC 61000-4-x series: Testing and measurement techniques for EMC, including immunity tests such as ESD, radiated immunity, and surge immunity.

6.3. Compliance Process

The general compliance process involves:

- Identifying Applicable Standards: Determine which standards apply to your product based on its intended use and market.

- Testing: Conduct the required EMC tests at an accredited test laboratory.

- Documentation: Prepare a compliance report detailing the test results and demonstrating that the product meets the applicable standards.

- Declaration of Conformity: For products sold in the EU, issue a Declaration of Conformity (DoC) stating that the product complies with the relevant directives.

- Marking: Apply the appropriate compliance markings, such as the CE mark for products sold in the EU.

6.4. Maintaining Compliance

Compliance is not a one-time event. It is important to:

- Monitor Changes: Keep up-to-date with changes to EMC standards and regulations.

- Re-test: Re-test products if there are significant design changes that could affect EMC performance.

- Audit: Conduct regular internal audits to ensure that EMC procedures are being followed.

7. The Future of EMC Engineering

The field of EMC engineering is constantly evolving to meet the challenges posed by new technologies and increasing complexity of electronic systems. Emerging trends include the use of artificial intelligence (AI) and machine learning (ML) in EMC design, the development of new shielding materials, and the integration of EMC considerations into the design of 5G and beyond wireless systems.

7.1. AI and Machine Learning in EMC

AI and ML techniques can be used to automate EMC design tasks, optimize shielding and filtering, and predict EMC performance. These technologies can analyze large datasets of EMC measurements and simulations to identify patterns and relationships that can be used to improve EMC performance.

Applications of AI and ML in EMC:

- Automated EMC Design: Use AI algorithms to generate EMC-compliant designs automatically.

- Optimized Shielding and Filtering: Use ML algorithms to optimize the placement and configuration of shielding and filtering components.

- Predictive Modeling: Use AI algorithms to predict the EMC performance of electronic systems based on design parameters.

7.2. New Shielding Materials

New shielding materials are being developed to provide higher levels of shielding effectiveness at lower weights and costs. These materials include metamaterials, which can be engineered to exhibit unique electromagnetic properties, and self-healing materials, which can repair damage to shielding structures.

Types of New Shielding Materials:

- Metamaterials: Engineered materials with electromagnetic properties not found in nature.

- Self-Healing Materials: Materials that can repair damage to shielding structures automatically.

- Lightweight Composites: Composites with high shielding effectiveness and low weight.

7.3. EMC for 5G and Beyond

The development of 5G and beyond wireless systems poses new EMC challenges due to the higher frequencies and increased complexity of these systems. EMC engineers must develop new techniques to ensure that these systems can operate reliably without causing interference to other devices.

EMC Challenges for 5G and Beyond:

- Higher Frequencies: Higher frequencies are more susceptible to interference.

- Increased Complexity: 5G and beyond systems are more complex than previous generations of wireless systems.

- Densification: The increasing density of wireless devices increases the potential for interference.

8. Practical Tips for EMC Troubleshooting

Even with careful design and testing, EMC problems can still arise. Troubleshooting EMC issues requires a systematic approach and a good understanding of EMC principles.

8.1. Basic Troubleshooting Steps

- Identify the Problem: Clearly define the nature of the EMC issue. Is it an emission problem, an immunity problem, or both?

- Gather Information: Collect as much information as possible about the problem. When does it occur? Under what conditions? Which devices are affected?

- Isolate the Source: Try to isolate the source of the problem. Disconnect or disable potential sources of interference one at a time to see if the problem goes away.

- Test and Measure: Use EMC test equipment to measure emissions and immunity levels. This can help pinpoint the source of the problem and evaluate the effectiveness of mitigation measures.

- Implement Mitigation Measures: Implement appropriate mitigation measures, such as shielding, filtering, or grounding.

- Verify the Solution: After implementing mitigation measures, re-test the system to verify that the problem has been resolved.

8.2. Common EMC Problems and Solutions

- Emissions Problems:

- Problem: Excessive radiated emissions.

- Solution: Improve shielding, add filters, optimize PCB layout.

- Problem: Excessive conducted emissions.

- Solution: Add filters to power and signal lines, improve grounding.

- Immunity Problems:

- Problem: System malfunctions when exposed to ESD.

- Solution: Improve ESD protection, add transient voltage suppressors (TVS diodes).

- Problem: System malfunctions when exposed to radiated fields.

- Solution: Improve shielding, add filters, optimize cable routing.

- Grounding Problems:

- Problem: Ground loops causing noise and interference.

- Solution: Implement single-point grounding, use ground planes, avoid long ground loops.

- Cable Problems:

- Problem: Cables radiating emissions or conducting interference.

- Solution: Use shielded cables, optimize cable routing, add ferrite beads.

8.3. Using Diagnostic Tools

Several diagnostic tools can be used to troubleshoot EMC problems:

- Spectrum Analyzers: Used to measure the frequency and amplitude of electromagnetic signals.

- Near-Field Probes: Used to measure electromagnetic fields close to a device.

- Oscilloscopes: Used to visualize and analyze electrical signals.

- LISNs (Line Impedance Stabilization Networks): Used to provide a stable impedance for conducted emissions measurements.

9. The Human Element in EMC Engineering

While technology plays a crucial role in EMC engineering, the human element—including knowledge, expertise, and ethical considerations—is equally vital.

9.1. Importance of Training and Education

- Building Competency: Adequate training and education are essential for engineers and technicians working in EMC. A strong understanding of EMC principles, standards, and best practices ensures that they can effectively design, test, and troubleshoot electronic systems.

- Staying Current: The field of EMC is continuously evolving, with new technologies and standards emerging regularly. Ongoing training and education are necessary to stay current with these developments.

9.2. Ethical Considerations

- Honesty and Integrity: EMC engineers have a responsibility to ensure that electronic devices meet the required emission and immunity levels. Ethical conduct requires honesty and integrity in testing, reporting, and compliance activities.

- Public Safety: EMC engineering is critical for ensuring the safety of electronic systems in a wide range of applications. Ethical engineers prioritize public safety and take all necessary steps to minimize the risk of EMI-related hazards.

9.3. Collaboration and Communication

- Teamwork: EMC engineering often involves collaboration with other engineering disciplines, such as electrical, mechanical, and software engineering. Effective teamwork and communication are essential for addressing EMC challenges and ensuring that all aspects of the system are properly designed and tested.

- Documentation: Clear and comprehensive documentation is crucial for EMC compliance and troubleshooting. Documentation should include design specifications, test plans, test results, and mitigation measures.

10. Conclusion: Embracing EMC Engineering for a Safer, More Reliable World

EMC engineering is vital for ensuring the safe and reliable operation of electronic systems. By understanding EMC principles, following best practices, and adhering to regulatory standards, engineers can minimize the risk of EMI-related problems and create a safer, more reliable world. CONDUCT.EDU.VN provides comprehensive resources and guidance to help professionals excel in EMC engineering.

Key Takeaways:

- EMC engineering is essential for safety, reliability, compliance, and performance.

- The EMC design process involves planning, circuit and PCB design, shielding, grounding, filtering, and cable management.

- EMC testing is critical for verifying compliance with regulatory standards.

- EMC for functional safety is essential for safety-related applications.

- Advanced EMC engineering techniques include modeling and simulation, near-field scanning, and advanced shielding materials.

- Regulatory compliance and standards are necessary for market access.

- The future of EMC engineering involves AI, new shielding materials, and EMC for 5G and beyond.

- Practical troubleshooting tips can help resolve EMC problems.

- The human element, including training, ethics, and collaboration, is crucial in EMC engineering.

For more detailed information and guidance on EMC engineering, visit conduct.edu.vn. Our comprehensive resources, expert advice, and practical tools will help you master the principles and practices of EMC engineering and ensure the safety and reliability of your electronic systems. Contact us at 100 Ethics Plaza, Guideline City, CA 90210, United States. Reach out via Whatsapp at +1 (707) 555-1234.

Frequently Asked Questions (FAQ) About EMC Engineering

1. What is electromagnetic compatibility (EMC)?

Electromagnetic compatibility (EMC) is the ability of electronic equipment and systems to function satisfactorily in their electromagnetic environment without introducing intolerable electromagnetic disturbances to other equipment in that environment.

2. Why is EMC important?

EMC is important because electromagnetic interference (EMI) can cause malfunctions in electronic systems, leading to safety hazards, reduced reliability, and non-compliance with regulatory standards.

3. What are the basic principles of EMC design?

The basic principles of EMC design include minimizing loop areas, using ground planes, proper component placement, decoupling capacitors, signal routing, shielding, grounding, and filtering.

4. What is the difference between emissions and immunity?

Emissions refer to the electromagnetic energy intentionally or unintentionally generated by a device. Immunity refers to the ability of a device to function correctly in the presence of electromagnetic disturbances.

5. What are some common EMC testing standards?

Common EMC testing standards include FCC Part 15, CISPR standards, IEC standards, and EN standards.

6. What is EMC for functional safety?

EMC for functional safety is the application of EMC principles to safety-related electronic systems to minimize the risk of EMI-related hazards.

7. How is risk assessment used in EMC for functional safety?

Risk assessment involves identifying potential hazards, assessing the likelihood and severity of those hazards, and implementing measures to reduce the associated risks.

8. What are some common EMC mitigation strategies?

Common EMC mitigation strategies include shielding, filtering, redundancy, diversity, and monitoring.

9. What are some advanced EMC engineering techniques?

Advanced EMC engineering techniques include modeling and simulation, near-field scanning, and the use of advanced shielding materials.

10. How can AI and machine learning be used in EMC engineering?

AI and machine learning can be used to automate EMC design tasks, optimize shielding and filtering, and predict EMC performance.