When crafting an effective machine vision system, lighting is paramount. The optimal lighting solution depends on understanding two key aspects: the immediate inspection environment and how the light interacts with the sample. By evaluating these elements alongside available optics, lighting types, techniques, and the fundamental principles of machine vision, you can develop a lighting solution that meets the required acceptance criteria.

Immediate Inspection Environment

A thorough understanding of the physical requirements and limitations of the inspection area, in three dimensions, is crucial. The use of robotic pick-and-place machines or essential support structures can significantly limit the choice of effective lighting solutions. This limitation often requires compromises in lighting type, geometry, working distance, intensity, and pattern.

For instance, a diffuse light source might be ideal, but physical constraints may prevent its implementation due to limited top-down access. High-speed production lines might need intense continuous light or strobe lighting to freeze motion. Inspecting large objects presents a distinct challenge. Consistent part placement and presentation are also important, particularly for specific features being inspected. Lighting strategies can be developed to address inconsistencies in part placement and presentation if the factors are well understood.

Ambient Light Contribution

Ambient light can significantly impact the quality and consistency of machine vision inspections, especially when using multispectral light sources like white light. Common sources of ambient light include overhead factory lights and sunlight, but stray task lighting from nearby inspection stations can also interfere.

There are three main methods to mitigate the effects of ambient light:

- High-power strobing with short duration pulses: This method overwhelms ambient light, but may have drawbacks in ergonomics, cost, and implementation. Not all light sources, like fluorescent lights, are suitable for strobing.

- Physical enclosures: Enclosures block external light, providing a controlled environment.

- Pass filters: These filters selectively allow specific wavelengths of light to pass through, blocking unwanted ambient light.

The choice of method depends on various factors. If a color camera is used and strobing is not feasible, multispectral white light is usually needed for accurate color reproduction. In this case, enclosures are often the best option, as narrow wavelength pass filters would block much of the white light.

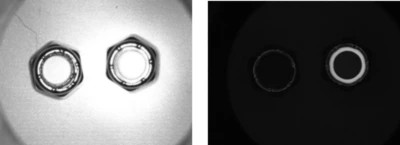

However, there are exceptions. For example, a 700 nm short pass filter (IR blocker) is standard in color cameras to prevent infrared light from affecting color accuracy, especially in the green channel. The figure below demonstrates the effectiveness of a pass filter in blocking ambient light.

Sample/Light Interactions

The way a sample’s surface interacts with task-specific and ambient light depends on factors such as its shape, geometry, reflectivity, composition, topography, and color. These factors determine how much light is reflected to the camera, influencing acquisition, processing, and measurement. A curved, specular surface (e.g., the bottom of a soda can) reflects light differently than a flat, diffuse surface (e.g., copy paper). Similarly, a topographic surface (e.g., a populated PCB) reflects light differently than a flat, textured surface, depending on the lighting type and geometry. The following figures illustrate this concept.

Color Analysis

Materials reflect and absorb different wavelengths of light to varying degrees, an effect applicable to both black and white and color imaging. Similar colors reflect, brightening surfaces, while opposing colors absorb, darkening them. A color wheel (Figure 8) can be used to generate differential contrast between a part and its background (Figure 9). Even with a black and white camera, color parts can be differentiated with a known palette of colors (Figure 10).

Sample Composition and Transmittance

A sample’s composition greatly influences how light interacts with it. Some plastics may only transmit specific wavelength ranges, while others may internally diffuse light or absorb and re-emit it (fluorescence). Fluorescent labels and dyes are frequently used in the printing industry, as illustrated below.

Infrared (IR) light is useful for vision inspection because it neutralizes contrast differences based on color, reflecting based on composition rather than color. This is useful when you want to minimize contrast normally based on color reflectance from white light.

IR light penetrates polymer materials better than shorter wavelengths like UV, blue, and even red in some instances. Conversely, blue light is more effective for imaging shallow surface features of black rubber compounds or laser etchings due to its lack of penetration depth.

Polarizing filters, used in pairs between the light source and sample and between the sample and camera (typically attached to the lens), help detect structural lattice damage in transparent samples.

However, using polarizing filters involves trade-offs, especially in blocking specular reflections. Glare from curved surfaces may be controlled but not entirely eliminated with polarization filters due to multiple reflection directions from a directional light source. In such cases, adjusting the lighting geometry (e.g., moving the light off-axis) can be more effective. For relatively flat surfaces, polarizers can largely remove specular glare, but can also reduce the available light considerably, which can be detrimental for high-speed inspections.

Conclusion

Selecting the correct lighting for a machine vision application involves a comprehensive understanding of the inspection environment, how light interacts with the sample, and the available tools and techniques. By carefully considering these factors, you can optimize your machine vision system for accuracy, reliability, and efficiency. This practical guide provides a solid foundation for making informed decisions about machine vision lighting, leading to improved inspection results.