The fashion industry involves more than just creative designs; numbers play a crucial role. For those not deeply involved in the numerical aspects, terms like size charts, spec charts, and grade rules can be confusing. While they may seem similar, each has a distinct meaning and purpose. This guide will clarify these terms, focusing primarily on how size guides work, and explain their importance for both consumers and designers.

Size Charts: Your Customer-Facing Measurement Guide

A size chart is a customer-facing resource designed to help shoppers determine the correct size to order. This chart is typically found on a brand’s website or product pages.

Understanding the Numbers

The numbers on a size chart represent body measurements, not garment measurements. This is a critical distinction. The size chart provides general body measurements corresponding to each size, not the exact measurements of a specific garment.

Size Chart Example

Size Chart Example

Alt text: Example of a garment spec chart showing measurements for different sizes and points of measure.

Using a Size Chart Effectively

The primary purpose of a size chart is to assist customers in selecting the size that will fit them best. To use a size chart effectively, customers need to measure their own body and compare those measurements to the chart. The size that most closely matches their measurements is generally the recommended size to order.

In addition to a general size chart, brands often provide specific notes about the fit and sizing of individual garments on their product pages. This might include information about how fitted a garment is, its length, inseam, or recommendations for sizing up or down based on desired fit.

Spec Charts: Internal Tools for Development, Production, and Quality Control

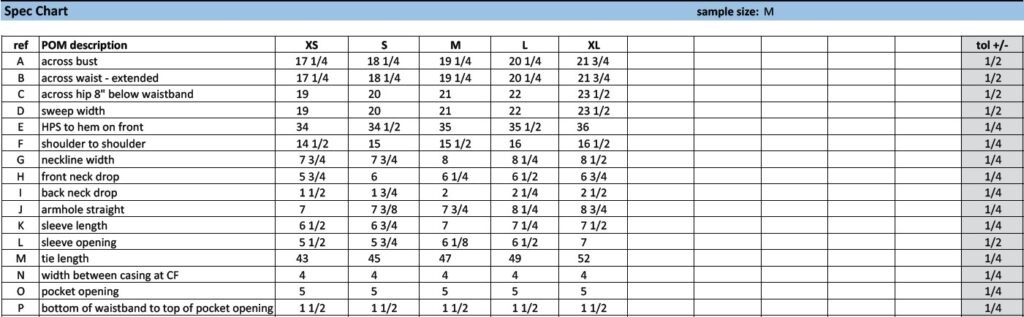

Spec charts, also known as spec sheets, graded specs, or garment POMs (points of measure), are used internally by designers, manufacturers, and for quality control. They are included as part of the tech pack for each garment.

Understanding the Numbers

Unlike size charts, spec charts display garment measurements. They detail where each measurement is taken on the garment and the expected measurement for each size within the range.

Spec charts also include a tolerance column. This accounts for the margin of error inherent in cutting, sewing, and fabric properties. The tolerance indicates the acceptable variation in measurement for each point of measure. For example, a tolerance of ½” on a bust measurement of 19 ¼” for a size M means that a measurement between 18 ¾” and 19 ¾” is considered acceptable.

The spec chart measurements are closely related to pattern measurements, though not always identical.

Using a Spec Chart Effectively

Spec charts have multiple uses:

- Development: Requesting specific sample measurements from patternmakers or factories (e.g., sleeve length, skirt length, waistband size).

- Quality Control: Comparing finished samples against the spec chart to ensure they fall within acceptable tolerances. Discrepancies should be investigated before making any changes during fitting.

- Production: Serving as a quality check for finished garments by both the designer and the factory. The tech pack, including the spec chart, functions as an informal contract, ensuring mutual understanding of expectations and acceptable quality standards.

Grade Rules: Scaling Patterns Consistently

A grade rule is a technical set of numbers used by patternmakers or graders to create different sizes from a base or sample size. Designers typically don’t directly use grade rules unless they are doing their own pattern grading. If a brand doesn’t have established grade rules, a patternmaker or grader can develop them based on the size chart or spec chart.

Understanding the Numbers

Grade rule numbers represent amounts of movement, indicating how much (and in which direction) a specific point moves between adjacent sizes along the X and Y axes. A grade rule is a compilation of these movements for each point and size. The base size (e.g., size M) serves as the reference point, with all other sizes graded from it.

These numbers can be shown as cumulative deviations from the base size or as movements from the previous adjacent size.

It’s important to note that grade rules are distinct from spec charts. Grade rules show the differences between sizes, while spec charts show the finished sizes themselves. Spec charts can illustrate how much a point of measure changes between sizes, but only the grade rule provides a complete picture of where that growth occurs within the garment.

Using a Grade Rule Effectively

Grade rules are used to grade patterns from the base size into all the other sizes offered. Digital patterns store grade rules in ‘.rul’ files, and CAD patternmaking software allows importing and exporting grade rules. Grade rules can also be created in spreadsheets and used as a reference to ensure consistent sizing across all styles within a brand.