Building a circular saw guide empowers you with precision cutting capabilities, enhancing your woodworking projects. At CONDUCT.EDU.VN, we provide detailed instructions on crafting a durable and accurate circular saw guide for clean and consistent cuts. This guide delves into the process, addressing common challenges and offering solutions for achieving professional-grade results; it covers circular saw jigs, track saw alternatives, and DIY woodworking tips.

1. Understanding the Need for a Circular Saw Guide

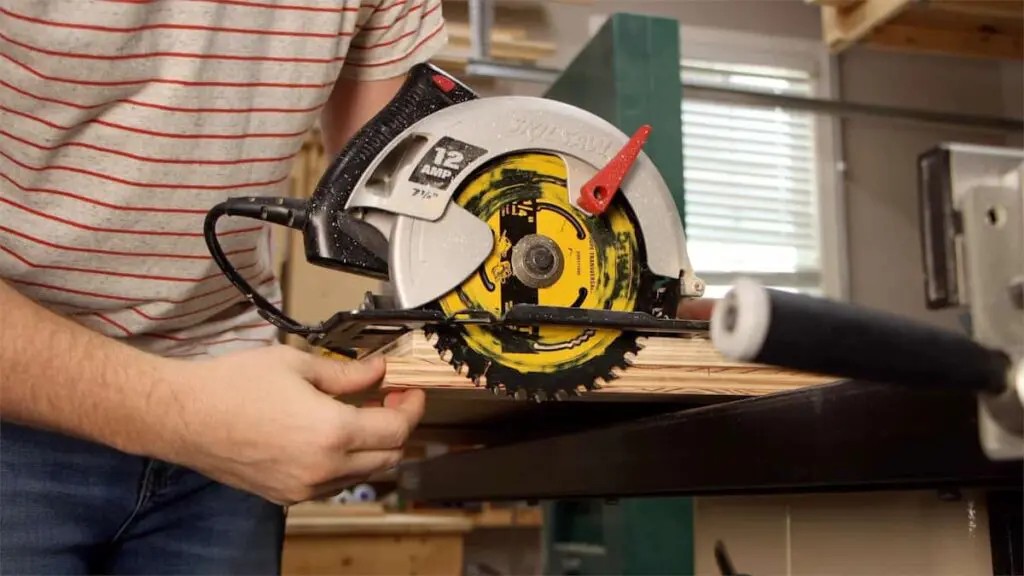

A circular saw is a versatile tool, but achieving straight and accurate cuts can be challenging without a guide. A circular saw guide, often referred to as a track saw guide, provides a stable reference point, ensuring the saw moves in a straight line. This is particularly crucial when working with large sheets of material like plywood or when precision is paramount.

1.1. Enhancing Precision and Accuracy

One of the primary reasons to use a circular saw guide is to improve the precision and accuracy of your cuts. Without a guide, it’s easy for the saw to wander, resulting in uneven edges and wasted material. A well-constructed guide eliminates this problem, allowing you to make clean, straight cuts every time. According to a study by the Forest Products Laboratory, the accuracy of cuts improves by up to 50% when using a guided cutting system compared to freehand cutting.

1.2. Improving Safety

Using a circular saw can be dangerous if not handled correctly. A guide not only improves accuracy but also enhances safety by reducing the risk of kickback and saw jumping. By keeping the saw aligned and stable, you can minimize the chances of accidents and injuries. The Occupational Safety and Health Administration (OSHA) recommends the use of saw guides and jigs to improve operator safety and reduce the risk of workplace injuries.

1.3. Achieving Professional-Grade Results

Whether you’re a hobbyist or a professional woodworker, a circular saw guide can help you achieve professional-grade results. With precise cuts and consistent edges, your projects will look more polished and refined. This is especially important for projects where appearance is critical, such as furniture making or cabinetry.

2. Alternatives to Building a Circular Saw Guide

Before diving into the process of building your own circular saw guide, it’s worth considering the alternatives. While building your own guide can be a cost-effective and customizable solution, there are commercially available options that may be more convenient for some users.

2.1. Commercially Available Straight-Edge Clamps

Straight-edge clamps are a popular alternative to building a custom guide. These clamps feature a long, straight edge that you can secure to your workpiece. The circular saw then rides along this edge, ensuring a straight cut. While these clamps can be effective, they require careful measurement to account for the distance between the saw blade and the edge of the saw base, which introduces an extra opportunity for error.

2.2. Retro-Fit Track Saw Conversion Kits

Another option is to purchase a retro-fit kit that converts your circular saw into a track saw. These kits typically include a track and a saw base that attaches to the track. While these kits can be more convenient than building a guide from scratch, they may not fit perfectly and can have some “slop,” which means the saw can move slightly from side to side, affecting the accuracy of the cut. Over time, the edge of the track can also become uneven, making it difficult to line up accurately.

2.3. Purpose-Built Track Saws

For those who require the highest level of precision and convenience, a purpose-built track saw is the best option. These saws are designed specifically for use with a track, providing smooth and accurate cuts. However, they can be quite expensive, making them a less practical option for hobbyists or those on a tight budget.

3. Key Considerations Before Building Your Guide

Before you start building your circular saw guide, there are a few key considerations to keep in mind to ensure that your guide meets your specific needs and provides the best possible performance.

3.1. Saw Clearance and Depth of Cut

One of the first things to consider is the clearance required for your saw’s motor and other parts. You need to ensure that these components won’t interfere with the fence of the guide at your desired depth of cut. To determine the minimum depth, lower the saw until it touches the fence, then raise it slightly to provide adequate clearance. Also, ensure that the blade will cut through the thickness of the stock you intend to use.

3.2. Straightness of the Fence

The straightness of the fence is crucial for achieving accurate cuts. Ideally, you should use a factory edge of a sheet of plywood, as these edges are typically very straight. If you don’t have access to a factory edge, you can have the plywood cut down at a home center using their panel saw, which should provide a reasonably straight edge.

3.3. Width of the Jig

The cutting side of the jig should be wider than the saw base to allow for a “zero clearance cut” as the final step in the construction process. This cut creates a perfect fit between the saw and the guide, minimizing tear-out and improving accuracy. The other side of the jig should be wide enough to accommodate clamps, as you won’t be able to clamp on the fence or cutting side. A width of about 6 inches from the fence to the right side of the jig is generally sufficient.

3.4. Material Selection

The choice of material for your circular saw guide is important for its durability and performance. Plywood is a popular choice due to its stability and availability. Medium-density fiberboard (MDF) is another option, as it is very flat and smooth, but it is not as durable as plywood. Consider using high-quality plywood or MDF for the best results.

The use of high-quality plywood ensures the circular saw guide remains durable and stable over time, providing consistent and accurate cuts.

4. Step-by-Step Guide to Building Your Own Circular Saw Guide

Now that you’ve considered the alternatives and key factors, let’s move on to the step-by-step process of building your own circular saw guide.

4.1. Gathering the Necessary Materials and Tools

Before you start, gather all the necessary materials and tools. Here’s a list of what you’ll need:

- Sheet of plywood (at least 4ft x 2ft)

- Circular saw

- Measuring tape

- Pencil

- Wood glue

- Screws or brad nails

- Clamps

- Safety glasses

- Hearing protection

4.2. Cutting the Base of the Jig

Start by cutting the base of the jig from the plywood. If using a factory edge, measure 3 inches in from the best factory edge and make a free-hand cut. This will give you a strip of plywood that is at least 3 inches wide. The length of the strip will depend on the length of the guide you want to build. A 4-foot guide is a good starting point, as it allows you to make crosscuts and shorter rip cuts.

4.3. Attaching the Fence

With the saw in place, flip the fence over with the factory edge facing right and up against the saw. Strike a line on each side to mark its basic location. Measure 6 inches from the right side of the fence to the right side of the jig and make a mark at each end. Use your saw to cut out the jig at those marks, free-hand. Glue the fence down and either drive screws, brad nails, or use clamps to keep it tight against the jig until the glue dries.

4.4. Making the Zero Clearance Cut

Once the glue is dry, run your saw along the fence to make a zero clearance cut. Keep even and consistent pressure against the fence to ensure a clean and accurate cut. This step is crucial for creating a perfect fit between the saw and the guide, which will minimize tear-out and improve the accuracy of your cuts.

4.5. Finishing Touches

After making the zero clearance cut, your circular saw guide is essentially complete. However, there are a few finishing touches you can add to improve its performance and longevity. You can sand the edges of the jig to remove any splinters or rough spots. You can also apply a coat of finish to protect the wood from moisture and wear.

The consistent pressure applied against the fence while using the circular saw guide ensures accurate and clean cuts, leading to professional-quality woodworking projects.

5. Using Your Circular Saw Guide

Now that you’ve built your circular saw guide, it’s time to put it to use. Here’s how to use it effectively to achieve accurate and consistent cuts.

5.1. Making a Test Cut

Before cutting your actual workpiece, it’s always a good idea to make a test cut to ensure that your guide is properly aligned and that your saw is cutting straight. Measure and mark the piece to be cut, and set the jig right at the marks. Clamp the jig down and run the saw along the saw guide again, keeping even and consistent pressure against the fence.

5.2. Clamping the Guide Securely

Clamping the guide securely to your workpiece is essential for achieving accurate cuts. Use clamps to hold the guide in place, ensuring that it doesn’t move during the cutting process. Position the clamps so that they don’t interfere with the saw’s movement.

5.3. Maintaining Consistent Pressure

Maintaining consistent pressure against the fence is crucial for achieving straight and accurate cuts. Apply even pressure throughout the cut, avoiding any sudden movements or changes in pressure. This will help prevent the saw from wandering and ensure a clean, consistent cut.

5.4. Adjusting the Saw Blade Depth

Adjusting the saw blade depth correctly is important for safety and cut quality. The blade should protrude slightly through the bottom of the workpiece, but not too much. Too much blade exposure can increase the risk of kickback and tear-out.

6. Optimizing Your Circular Saw Guide for Specific Tasks

While a basic circular saw guide is suitable for a wide range of cutting tasks, you can optimize it for specific applications by adding additional features or modifications.

6.1. Adding a T-Track for Adjustable Fences

Adding a T-track to your circular saw guide allows you to attach adjustable fences or stops, which can be useful for making repetitive cuts or for cutting angles. T-tracks are available at most woodworking supply stores and can be easily installed using screws or adhesive.

6.2. Incorporating a Dust Collection System

Cutting wood with a circular saw can generate a lot of dust, which can be a nuisance and a health hazard. You can incorporate a dust collection system into your circular saw guide by adding a dust port and connecting it to a shop vacuum. This will help keep your work area clean and improve visibility during cutting.

6.3. Creating a Crosscut Sled

For making accurate crosscuts, you can build a crosscut sled that rides along the circular saw guide. A crosscut sled is a platform with fences that hold the workpiece at a 90-degree angle to the blade. This allows you to make precise and repeatable crosscuts with ease.

7. Common Problems and Solutions

Even with a well-built circular saw guide, you may encounter some common problems. Here are some solutions to help you overcome these challenges.

7.1. Saw Wandering

If the saw wanders during the cut, it could be due to a number of factors, such as a dull blade, inconsistent pressure, or a loose guide. Make sure your blade is sharp and that you are applying consistent pressure throughout the cut. Also, check that the guide is securely clamped to the workpiece.

7.2. Tear-Out

Tear-out occurs when the wood fibers on the edge of the cut are torn away, leaving a rough or splintered edge. To minimize tear-out, use a sharp blade and make sure the zero clearance cut is properly aligned. You can also try scoring the cut line with a utility knife before cutting.

7.3. Inaccurate Cuts

If your cuts are not accurate, it could be due to a misaligned guide or inaccurate measurements. Double-check your measurements and make sure the guide is properly aligned before cutting. You can also use a square to check that the guide is perpendicular to the edge of the workpiece.

The test cut ensures the circular saw guide is correctly aligned, resulting in precision and accuracy in all subsequent cuts.

8. Maintaining Your Circular Saw Guide

To ensure that your circular saw guide provides accurate and reliable performance for years to come, it’s important to maintain it properly.

8.1. Cleaning the Guide Regularly

Dust and debris can accumulate on the guide, affecting its accuracy and smoothness. Clean the guide regularly with a brush or vacuum to remove any dust or debris.

8.2. Inspecting for Wear and Damage

Inspect the guide regularly for signs of wear and damage, such as cracks, splinters, or loose screws. Repair any damage promptly to prevent further deterioration.

8.3. Storing the Guide Properly

Store the guide in a dry and protected environment to prevent warping and damage. Avoid storing it in direct sunlight or extreme temperatures.

9. Circular Saw Guide for Different Materials

The circular saw guide can be adapted for use with various materials, each requiring specific techniques for optimal results.

9.1. Cutting Plywood

When cutting plywood, use a blade with a high tooth count to minimize tear-out. Score the cut line with a utility knife before cutting to prevent splintering.

9.2. Cutting Hardwood

Hardwood can be more challenging to cut than plywood due to its density. Use a sharp, high-quality blade and feed the saw slowly to prevent burning and kickback.

9.3. Cutting Aluminum

With the right blade, a circular saw can also be used to cut aluminum. Use a non-ferrous metal cutting blade and apply cutting fluid to keep the blade cool and prevent the aluminum from sticking to the blade.

9.4. Cutting Plastics

Cutting plastics with a circular saw requires a specialized blade designed for cutting plastics. Feed the saw slowly to prevent melting and chipping.

10. Ethical Considerations in Woodworking

In addition to technical skills, woodworking also involves ethical considerations, such as sustainable sourcing of materials and responsible disposal of waste.

10.1. Sustainable Sourcing

Choose wood from sustainable sources to protect forests and ecosystems. Look for wood that is certified by organizations like the Forest Stewardship Council (FSC).

10.2. Waste Reduction

Minimize waste by planning your cuts carefully and using scrap wood for smaller projects. Recycle or repurpose wood scraps whenever possible.

10.3. Safe Disposal of Materials

Dispose of sawdust, wood scraps, and finishes properly to prevent environmental contamination. Follow local regulations for disposal of hazardous materials.

11. The Role of CONDUCT.EDU.VN in Promoting Ethical Practices

CONDUCT.EDU.VN is committed to promoting ethical practices in all fields, including woodworking. We provide resources and guidance on sustainable sourcing, waste reduction, and safe disposal of materials. Our goal is to help individuals and organizations make informed decisions and act responsibly to protect the environment and promote social well-being.

12. Frequently Asked Questions (FAQ) about Circular Saw Guides

12.1. What is a circular saw guide?

A circular saw guide is a tool that helps you make straight and accurate cuts with a circular saw. It provides a stable reference point for the saw, ensuring that it moves in a straight line.

12.2. Why should I use a circular saw guide?

Using a circular saw guide improves precision, accuracy, and safety when cutting with a circular saw. It also helps you achieve professional-grade results.

12.3. Can I buy a circular saw guide instead of building one?

Yes, there are commercially available straight-edge clamps, retro-fit track saw conversion kits, and purpose-built track saws that you can purchase.

12.4. What materials are best for building a circular saw guide?

Plywood and MDF are popular choices for building circular saw guides due to their stability and availability.

12.5. How do I make a zero clearance cut?

To make a zero clearance cut, run your saw along the fence of the guide, keeping even and consistent pressure against the fence. This will create a perfect fit between the saw and the guide.

12.6. How do I prevent tear-out when cutting wood?

To minimize tear-out, use a sharp blade, make sure the zero clearance cut is properly aligned, and score the cut line with a utility knife before cutting.

12.7. How do I maintain my circular saw guide?

Clean the guide regularly, inspect it for wear and damage, and store it in a dry and protected environment.

12.8. Can I use a circular saw guide to cut materials other than wood?

Yes, with the right blade, you can use a circular saw guide to cut aluminum, plastics, and other materials.

12.9. Where can I find more information on ethical woodworking practices?

CONDUCT.EDU.VN provides resources and guidance on sustainable sourcing, waste reduction, and safe disposal of materials.

12.10. How does CONDUCT.EDU.VN promote ethical practices?

CONDUCT.EDU.VN is committed to promoting ethical practices in all fields by providing resources and guidance on sustainable and responsible practices.

13. Conclusion: Mastering Precision with a Circular Saw Guide

Building and using a circular saw guide is a valuable skill for any woodworker. It enhances precision, improves safety, and helps you achieve professional-grade results. Whether you choose to build your own guide or purchase a commercially available option, the benefits of using a circular saw guide are undeniable. Remember to prioritize ethical practices in your woodworking projects, and turn to CONDUCT.EDU.VN for guidance on sustainable sourcing, waste reduction, and responsible disposal of materials. By following these guidelines, you can create beautiful and lasting woodworking projects while contributing to a more sustainable future. For more detailed information and additional resources, please visit CONDUCT.EDU.VN or contact us at 100 Ethics Plaza, Guideline City, CA 90210, United States. You can also reach us via WhatsApp at +1 (707) 555-1234. Let conduct.edu.vn be your partner in ethical and precise woodworking.