Replacing valve guides seems straightforward, but it’s a task where precision matters. Many online discussions downplay the complexities involved. This guide delves into the crucial steps to change valve guides correctly, focusing on avoiding common pitfalls like cracking, which can lead to significant engine damage.

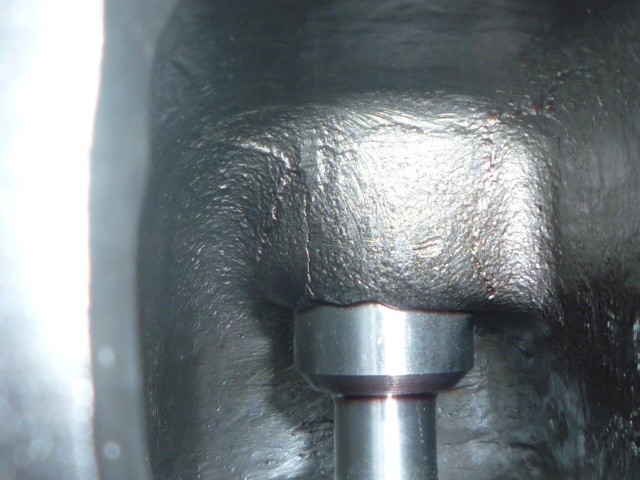

After entrusting my cylinder head to a specialist for machining and valve seat work, a thorough inspection revealed cracks emanating from the valve guides, visible through both intake and exhaust ports.

These cracks, while not immediately causing leaks, pose a severe risk. Fragments of cast iron can detach and become lodged between the valve and valve seat. The resulting damage can be catastrophic. Although exhaust gases might expel some debris, the intake side presents a different scenario. Engine operation introduces factors like heat expansion and vibration, exacerbating the problem.

The replacement valve guides used were standard Moss or Abingdon parts, installed without modification. However, the cracks indicate that the valve guides were potentially oversized, causing excessive stress on the cast iron head.

Cast iron, unlike steel, is brittle and prone to cracking under tension. Therefore, the press fit of the valve guides must be precise. An experienced machinist would recommend a press fit of no more than 0.02mm (one-hundredth of a millimeter). Achieving this requires accurate measurement of both the hole diameter in the cylinder head and the valve guide diameter, necessitating the use of a micrometer and a bore micrometer.

The devil is truly in the details. While the new valve guides were already installed, preventing measurement of the hole diameter, measurements of the removed valve guides revealed significant variations in diameter. The largest measured 14.06mm, while the smallest measured 14.03mm. This 0.03mm tolerance on the valve guides alone exceeds the ideal press fit. Considering potential variations in the hole diameters, the overall fit becomes even more unpredictable. The varying sizes of the observed cracks further suggest inconsistencies in the hole sizes.

This begs the question of how MG installed valve guides back in 1952. Perhaps they meticulously paired valve guides and cylinder heads with closely matched bore diameters. It’s also plausible that MG heated the cylinder head before installation to facilitate the process. One thing is certain: they likely didn’t resort to brute force.

The takeaway is that caution is paramount when installing new valve guides. Ignoring proper procedures can lead to cracks around all valve guides, indicating an overly tight press fit. Simply hammering the guides into place, as some might suggest, is a recipe for disaster. The process requires precision and care. Remember to always measure twice and install once.