Creating a cutting guide for circular saws ensures precision and safety in woodworking projects. CONDUCT.EDU.VN offers comprehensive guidance on crafting this essential tool, promoting accurate cuts and minimizing errors. This article explores the benefits of a circular saw guide, step-by-step instructions, and safety measures, enhancing your woodworking skills. Learn about jig construction, zero clearance cuts, and test cut procedures, including tips for consistent pressure and optimal results.

1. Understanding the Importance of a Cutting Guide

A cutting guide, often referred to as a track saw guide, is an indispensable tool for any woodworking enthusiast. It enhances precision, safety, and efficiency when using circular saws.

1.1. Enhancing Precision

Circular saws can be challenging to control freehand, especially when cutting large pieces of material such as plywood. A cutting guide provides a straight edge, ensuring accurate and consistent cuts every time.

- Consistent Cuts: Eliminates variations in cut quality.

- Straight Lines: Ensures the saw follows a precise path.

- Reduced Errors: Minimizes mistakes that can occur with freehand cutting.

1.2. Improving Safety

Safety is paramount in woodworking. A cutting guide reduces the risk of accidents by keeping the saw aligned and stable.

- Stable Saw Movement: Prevents the saw from veering off course.

- Reduced Kickback: Minimizes the chance of the saw kicking back.

- Controlled Environment: Allows for a safer cutting process.

1.3. Increasing Efficiency

With a cutting guide, you can work faster and more efficiently, reducing the time and effort required to complete your projects.

- Faster Cutting: Simplifies the cutting process.

- Less Rework: Reduces the need to correct errors.

- Optimized Material Use: Minimizes waste by ensuring accurate cuts.

2. Assessing Your Needs Before Building a Cutting Guide

Before you begin constructing your cutting guide, take the time to assess your specific needs. This will ensure that the guide is tailored to your projects and circular saw.

2.1. Determine the Length

The length of your cutting guide should depend on the types of cuts you typically make.

- Short Cuts: A 4-foot guide is suitable for crosscuts and shorter rip cuts.

- Long Cuts: An 8-foot guide is ideal for cutting full sheets of plywood.

- Versatile Guide: Consider a modular system that allows you to connect multiple sections for varying lengths.

2.2. Consider the Saw’s Specifications

Each circular saw has unique specifications that will impact the design of your cutting guide.

- Blade Offset: Measure the distance from the edge of the saw’s base to the blade.

- Motor Clearance: Ensure the guide provides enough clearance for the saw’s motor.

- Base Size: The width of the saw’s base will determine the minimum width of the guide.

2.3. Evaluate Material Thickness

The thickness of the materials you typically cut will influence the height and stability of your cutting guide.

- Thin Materials: A lower profile guide may suffice.

- Thick Materials: A taller guide provides better support and stability.

- Adjustable Height: Consider a design that allows you to adjust the height for different material thicknesses.

3. Essential Materials and Tools for Building a Cutting Guide

Gathering the right materials and tools is essential for a successful cutting guide project.

3.1. Materials List

- Plywood: Choose a high-quality plywood sheet, preferably ¾ inch thick, for the base and fence.

- Straight Edge: A metal ruler or level to ensure the fence is perfectly straight.

- Wood Glue: High-quality wood glue for a strong and durable bond.

- Screws: Wood screws for added reinforcement.

- Clamps: Various sizes for holding the fence in place while the glue dries.

- Sandpaper: For smoothing rough edges.

3.2. Tools Required

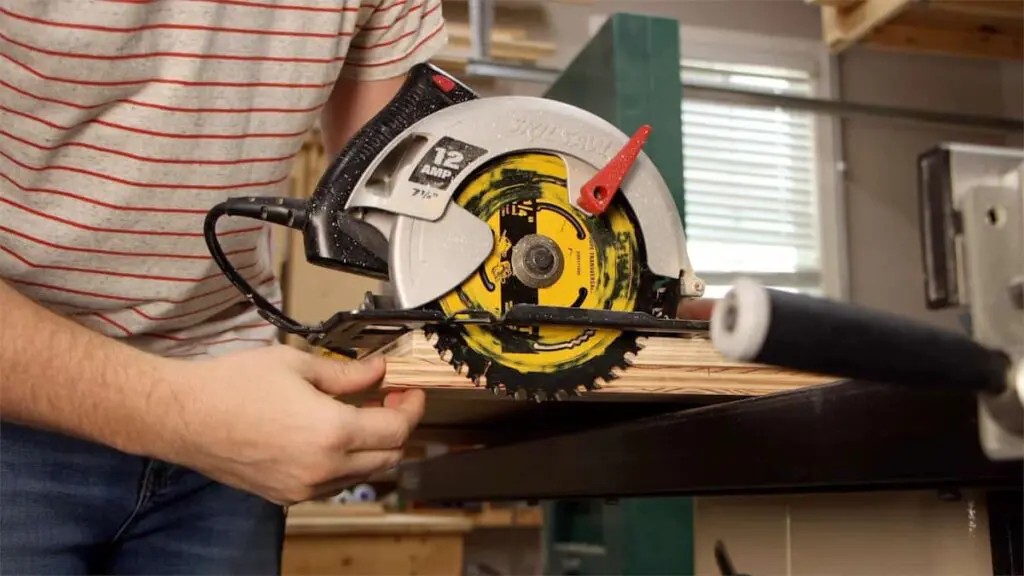

- Circular Saw: The same saw you will use with the guide.

- Drill: For pre-drilling screw holes.

- Screwdriver: For driving in screws.

- Measuring Tape: For accurate measurements.

- Pencil: For marking cut lines.

- Safety Glasses: To protect your eyes.

- Hearing Protection: To protect your ears from the noise of the saw.

3.3. Optional Enhancements

- T-Track: Install a T-track for added versatility and clamping options.

- Non-Slip Material: Apply non-slip tape to the bottom of the guide for added stability.

- Dust Collection Port: Add a port to connect a vacuum for dust collection.

4. Step-by-Step Guide to Building a Cutting Guide

Follow these detailed steps to construct a high-quality cutting guide for your circular saw.

4.1. Preparing the Base

- Cut the Base: Cut a piece of plywood to the desired length and width. A width of 12 inches is generally sufficient for stability.

- Ensure Straight Edge: Use a table saw or have the plywood cut at a home center to ensure one edge is perfectly straight.

- Sand the Edges: Smooth the edges with sandpaper to remove any splinters or rough spots.

4.2. Attaching the Fence

- Position the Fence: Place the straight edge along one side of the base, leaving enough room for the saw to run along it. Typically, 3 inches from the edge is adequate.

- Apply Glue: Apply a generous amount of wood glue to the edge of the base where the fence will be attached.

- Secure the Fence: Clamp the straight edge firmly against the base, ensuring it is perfectly aligned.

- Add Screws: Pre-drill holes and drive in wood screws every 6 inches to reinforce the glue joint.

- Allow to Dry: Let the glue dry completely, typically 24 hours, before proceeding.

4.3. Creating a Zero-Clearance Cut

- Mount the Saw: Place the circular saw on the base with the blade aligned to cut along the fence.

- Make the Cut: Turn on the saw and carefully run it along the fence, trimming the edge of the base. This creates a zero-clearance cut, ensuring the blade cuts right at the edge of the guide.

- Inspect the Cut: Check that the cut is clean and straight. The zero-clearance edge will help prevent splintering and improve accuracy.

4.4. Adding Optional Features

- Install T-Track: If desired, install a T-track along the base to allow for adjustable clamps and stops.

- Apply Non-Slip Material: Add non-slip tape or pads to the bottom of the guide to prevent it from sliding during use.

- Attach Dust Collection Port: If your saw has a dust port, consider adding a matching port to the guide for efficient dust collection.

5. Advanced Techniques for Cutting Guide Precision

To achieve the highest level of precision with your cutting guide, consider these advanced techniques.

5.1. Using Shims for Fine Adjustments

Shims can be used to make small adjustments to the fence, ensuring perfect alignment.

- Identify Misalignment: Use a precision square to check the alignment of the fence.

- Insert Shims: Place thin shims between the fence and the base to correct any misalignment.

- Re-Secure Fence: Tighten the clamps and screws to hold the fence in its adjusted position.

5.2. Incorporating a Sight Line

A sight line can help you align the guide precisely with your cut mark.

- Mark the Cut Line: Clearly mark the desired cut line on your workpiece.

- Add a Sight Line: Attach a thin piece of material along the edge of the guide, aligned with the blade’s cutting path.

- Align and Cut: Align the sight line with the cut mark for accurate cuts every time.

5.3. Building a Two-Piece Adjustable Guide

For even greater versatility, consider building a two-piece adjustable guide.

- Create Two Sections: Build two separate sections for the base, one slightly wider than the other.

- Attach Adjustment Mechanism: Install a mechanism, such as bolts and wingnuts, to allow you to adjust the width between the two sections.

- Adjust for Different Saws: This allows you to use the guide with different circular saws or to compensate for blade wear.

6. Safety Measures When Using a Cutting Guide

Safety should always be your top priority when using a cutting guide.

6.1. Wear Protective Gear

- Safety Glasses: Always wear safety glasses to protect your eyes from flying debris.

- Hearing Protection: Use earplugs or earmuffs to protect your hearing from the noise of the saw.

- Dust Mask: Wear a dust mask to prevent inhaling sawdust.

6.2. Secure the Workpiece and Guide

- Clamp the Workpiece: Secure the workpiece to a stable surface to prevent it from moving during the cut.

- Clamp the Guide: Clamp the cutting guide to the workpiece to ensure it stays in place.

6.3. Use Proper Cutting Techniques

- Maintain a Firm Grip: Hold the saw firmly with both hands.

- Use Consistent Pressure: Apply even pressure as you guide the saw along the fence.

- Avoid Overreaching: Position yourself so you do not have to overreach to make the cut.

6.4. Inspect the Equipment

- Check the Blade: Ensure the saw blade is sharp and in good condition.

- Inspect the Guide: Check the cutting guide for any damage or wear before each use.

- Test the Setup: Make a test cut to ensure the guide is properly aligned and secure.

7. Maintaining Your Cutting Guide

Proper maintenance will prolong the life of your cutting guide and ensure it continues to provide accurate cuts.

7.1. Cleaning

- Remove Sawdust: Regularly clean the guide with a brush or vacuum to remove sawdust and debris.

- Wipe Down Surfaces: Wipe down the surfaces with a damp cloth to remove any sticky residue.

7.2. Storage

- Store Flat: Store the cutting guide flat to prevent warping.

- Protect from Moisture: Keep the guide in a dry place to prevent moisture damage.

7.3. Repairing Damage

- Replace Worn Parts: Replace any worn or damaged parts, such as screws or clamps.

- Re-Glue Fence: If the fence becomes loose, re-glue and re-secure it with screws.

- Resurface Cutting Edge: If the cutting edge becomes damaged, resurface it with a sharp blade.

8. Common Mistakes to Avoid When Using a Cutting Guide

Avoiding these common mistakes will help you achieve better results and improve safety.

8.1. Not Securing the Workpiece

Failing to secure the workpiece can lead to inaccurate cuts and potential accidents.

- Solution: Always clamp the workpiece to a stable surface before making the cut.

8.2. Using a Dull Blade

A dull blade can cause splintering and make it difficult to control the saw.

- Solution: Use a sharp blade and replace it as needed.

8.3. Applying Too Much Pressure

Applying too much pressure can cause the saw to bind or veer off course.

- Solution: Let the saw do the work and apply even, consistent pressure.

8.4. Ignoring Safety Precautions

Ignoring safety precautions can lead to serious injuries.

- Solution: Always wear protective gear and follow proper cutting techniques.

9. Optimizing Cutting Guide Performance

Enhance the performance of your cutting guide by implementing these optimization strategies.

9.1. Choosing the Right Blade

Selecting the appropriate blade for the material you are cutting is crucial for achieving clean, accurate cuts.

- Plywood Blade: Use a blade with a high tooth count for cutting plywood to minimize splintering.

- Hardwood Blade: Choose a blade designed for hardwood to prevent tear-out.

- General Purpose Blade: A general-purpose blade can be used for a variety of materials, but may not provide the best results for specialized tasks.

9.2. Adjusting Saw Speed

Adjusting the speed of your circular saw can improve the quality of the cut, especially when working with different materials.

- Slower Speed: Use a slower speed for cutting hardwoods or thick materials to prevent burning.

- Higher Speed: A higher speed is suitable for softer materials like plywood or softwood.

9.3. Using Anti-Splinter Tape

Applying anti-splinter tape along the cut line can help prevent splintering and ensure a clean edge.

- Apply Tape: Place the tape along the cut line before making the cut.

- Cut Through Tape: The blade will cut through the tape, providing support to the wood fibers and reducing splintering.

10. Alternatives to a DIY Cutting Guide

If you prefer not to build your own cutting guide, there are several commercial options available.

10.1. Track Saws

Track saws are specialized circular saws designed to work with a guide rail.

- Integrated System: Offers a complete cutting solution with precise results.

- Higher Cost: Typically more expensive than a standard circular saw and DIY guide.

- Portable and Accurate: Provides portability and accuracy for professional use.

10.2. Clamp-On Straight Edges

Clamp-on straight edges provide a simple and effective way to guide your circular saw.

- Easy to Use: Clamps directly to the workpiece for a secure guide.

- Versatile: Can be used with different types of saws and materials.

- Less Precise: May not be as precise as a track saw or DIY guide.

10.3. Circular Saw Edge Guides

Circular saw edge guides attach directly to your saw and run along the edge of the workpiece.

- Compact and Lightweight: Easy to transport and use on the job site.

- Limited Width: Suitable for narrow cuts but may not work for wider pieces.

- Less Stable: Can be less stable than a track saw or DIY guide.

11. Real-World Applications of Cutting Guides

Cutting guides are used in a variety of woodworking projects to improve accuracy and efficiency.

11.1. Cabinet Making

In cabinet making, precise cuts are essential for creating seamless joints and professional-looking results.

- Accurate Panels: Ensures that cabinet panels are cut to the exact dimensions.

- Consistent Joinery: Helps create consistent and tight-fitting joints.

- Professional Finish: Contributes to a high-quality, professional finish.

11.2. Furniture Building

Whether you are building tables, chairs, or shelves, a cutting guide can help you achieve accurate and consistent cuts.

- Precise Dimensions: Ensures that furniture components are cut to the correct size.

- Square Cuts: Helps create square and stable furniture frames.

- Enhanced Aesthetics: Contributes to the overall aesthetic appeal of the finished piece.

11.3. Home Renovations

From installing flooring to building shelving, a cutting guide can be invaluable for home renovation projects.

- Accurate Flooring Cuts: Ensures that flooring planks are cut to the correct length and width.

- Straight Shelving: Helps create straight and level shelves.

- Improved Efficiency: Speeds up the renovation process and reduces errors.

12. Case Studies: Successful Cutting Guide Projects

Explore these case studies to see how cutting guides have been used to achieve outstanding results in various woodworking projects.

12.1. Building Custom Cabinets

A woodworker used a DIY cutting guide to build custom cabinets for a kitchen remodel.

- Challenge: Ensuring precise and consistent cuts for cabinet panels.

- Solution: Constructed a custom cutting guide using ¾ inch plywood and a metal straight edge.

- Result: The woodworker was able to cut all the panels with accuracy, resulting in a seamless and professional-looking cabinet installation.

12.2. Creating a Dining Table

A furniture maker used a track saw with a guide rail to build a large dining table.

- Challenge: Cutting large pieces of hardwood with precision.

- Solution: Utilized a track saw with a guide rail for accurate and splinter-free cuts.

- Result: The furniture maker was able to create a stunning dining table with clean lines and precise dimensions.

12.3. Installing Hardwood Flooring

A homeowner used a clamp-on straight edge to install hardwood flooring in their living room.

- Challenge: Cutting flooring planks to fit around doorways and corners.

- Solution: Employed a clamp-on straight edge to guide their circular saw.

- Result: The homeowner was able to achieve accurate and professional-looking flooring installation.

13. Troubleshooting Common Issues

Address these common issues to ensure your cutting guide performs optimally.

13.1. Guide Slipping During Cuts

If the guide slips during cuts, it can lead to inaccurate results and potential safety hazards.

- Solution: Ensure the guide is securely clamped to the workpiece. Consider adding non-slip material to the bottom of the guide.

13.2. Blade Binding

Blade binding can occur if the saw blade is not properly aligned or if the workpiece is not adequately supported.

- Solution: Check the alignment of the blade and ensure the workpiece is fully supported. Use a riving knife or splitter to prevent the wood from pinching the blade.

13.3. Splintering

Splintering can be a common issue when cutting certain types of wood, especially plywood.

- Solution: Use a blade with a high tooth count, apply anti-splinter tape, and adjust the saw speed.

14. Innovations in Cutting Guide Technology

Stay updated with the latest innovations in cutting guide technology to enhance your woodworking capabilities.

14.1. Smart Cutting Guides

Smart cutting guides incorporate electronic sensors and digital displays to provide real-time feedback and precise measurements.

- Laser Guidance: Uses lasers to project a precise cutting line on the workpiece.

- Digital Measurement: Provides digital readouts of cut length and angle.

- Automated Adjustments: Automatically adjusts the guide based on the material and desired cut.

14.2. Modular Cutting Systems

Modular cutting systems allow you to configure your cutting guide to meet the specific needs of your project.

- Interchangeable Components: Offers a range of interchangeable components, such as fences, clamps, and stops.

- Customizable Configurations: Allows you to create custom configurations for different cutting tasks.

- Versatile Applications: Suitable for a wide range of woodworking projects.

14.3. Wireless Connectivity

Some cutting guides offer wireless connectivity, allowing you to control and monitor the guide from your smartphone or tablet.

- Remote Control: Adjust settings and monitor performance from a remote location.

- Data Logging: Track cutting data and analyze performance over time.

- Software Integration: Integrates with woodworking software for seamless workflow.

15. The Future of Cutting Guides

The future of cutting guides promises even greater precision, efficiency, and safety.

15.1. AI-Powered Cutting Guides

AI-powered cutting guides will use artificial intelligence to optimize cutting parameters and prevent errors.

- Automated Adjustments: Automatically adjusts the guide based on the material, blade type, and desired cut.

- Error Detection: Detects potential errors and alerts the user before they occur.

- Predictive Maintenance: Predicts when maintenance is needed and schedules repairs.

15.2. Augmented Reality Integration

Augmented reality integration will allow you to visualize cuts and measurements in real-time using your smartphone or tablet.

- Virtual Cutting Lines: Projects virtual cutting lines onto the workpiece.

- Real-Time Measurements: Provides real-time measurements and feedback.

- Interactive Tutorials: Offers interactive tutorials and guidance.

15.3. Eco-Friendly Materials

Future cutting guides will be made from sustainable and eco-friendly materials.

- Recycled Materials: Uses recycled materials to reduce environmental impact.

- Biodegradable Components: Incorporates biodegradable components for easy disposal.

- Sustainable Manufacturing: Employs sustainable manufacturing processes to minimize carbon footprint.

16. Expert Tips for Cutting Guide Success

Benefit from these expert tips to maximize your cutting guide’s potential.

16.1. Invest in Quality Materials

Using high-quality materials will ensure that your cutting guide is durable and accurate.

- Premium Plywood: Choose premium plywood for the base and fence to prevent warping.

- Durable Clamps: Invest in durable clamps to securely hold the guide in place.

- Sharp Blades: Use sharp blades to achieve clean and accurate cuts.

16.2. Take Your Time

Rushing through the construction or setup process can lead to errors and potential safety hazards.

- Measure Carefully: Take your time to measure accurately and double-check your work.

- Secure Properly: Ensure all components are securely fastened before making the cut.

- Test Thoroughly: Test the setup thoroughly to identify any issues before starting the project.

16.3. Practice Regularly

Regular practice will help you develop your skills and improve your accuracy.

- Practice Cuts: Make practice cuts on scrap wood to get a feel for the guide.

- Experiment with Techniques: Experiment with different cutting techniques to find what works best for you.

- Seek Feedback: Seek feedback from experienced woodworkers to identify areas for improvement.

17. CONDUCT.EDU.VN: Your Resource for Woodworking Excellence

CONDUCT.EDU.VN is your ultimate resource for woodworking excellence, offering a wealth of information, guidance, and expert tips to help you master the craft.

17.1. Comprehensive Guides

Access our comprehensive guides on a wide range of woodworking topics, including cutting guides, joinery techniques, and finishing methods.

17.2. Expert Tutorials

Learn from our expert tutorials, featuring step-by-step instructions and detailed demonstrations.

17.3. Community Forum

Connect with fellow woodworkers in our community forum to share ideas, ask questions, and get feedback.

18. Ethical Considerations in Woodworking

In addition to technical skills, ethical considerations play a crucial role in woodworking.

18.1. Sustainable Sourcing

Choose wood from sustainable sources to protect forests and ecosystems.

- FSC Certification: Look for wood that is certified by the Forest Stewardship Council (FSC).

- Reclaimed Wood: Use reclaimed wood from old buildings or furniture.

- Local Suppliers: Support local suppliers who practice sustainable forestry.

18.2. Safe Practices

Follow safe practices to protect yourself and others from harm.

- Wear Protective Gear: Always wear safety glasses, hearing protection, and a dust mask.

- Use Proper Tools: Use the right tools for the job and maintain them properly.

- Follow Instructions: Follow the manufacturer’s instructions for all tools and materials.

18.3. Responsible Disposal

Dispose of waste materials responsibly to minimize environmental impact.

- Recycle: Recycle wood scraps, sawdust, and other waste materials.

- Compost: Compost sawdust and wood shavings.

- Proper Disposal: Dispose of hazardous materials, such as finishes and adhesives, properly.

19. FAQs About Cutting Guides for Circular Saws

Here are some frequently asked questions about cutting guides for circular saws:

-

What is the primary benefit of using a cutting guide?

- A cutting guide enhances precision, safety, and efficiency when using circular saws, ensuring accurate and consistent cuts.

-

What length of cutting guide should I choose?

- The length depends on your typical cuts: 4-foot for short cuts, 8-foot for long cuts, or a modular system for versatility.

-

What materials are essential for building a cutting guide?

- Essential materials include plywood, a straight edge, wood glue, screws, and clamps.

-

How do I create a zero-clearance cut?

- Mount the saw on the base and run it along the fence to trim the edge, creating a zero-clearance cut.

-

What safety measures should I take when using a cutting guide?

- Wear safety glasses, hearing protection, and a dust mask, and secure the workpiece and guide.

-

How do I maintain my cutting guide?

- Regularly clean the guide, store it flat, and repair any damage promptly.

-

What are common mistakes to avoid when using a cutting guide?

- Avoid not securing the workpiece, using a dull blade, and applying too much pressure.

-

What are alternatives to a DIY cutting guide?

- Alternatives include track saws, clamp-on straight edges, and circular saw edge guides.

-

How can I optimize my cutting guide performance?

- Choose the right blade, adjust saw speed, and use anti-splinter tape.

-

What are some innovations in cutting guide technology?

- Innovations include smart cutting guides, modular cutting systems, and wireless connectivity.

20. Call to Action: Enhance Your Woodworking Skills with CONDUCT.EDU.VN

Ready to take your woodworking skills to the next level? Visit CONDUCT.EDU.VN today to access comprehensive guides, expert tutorials, and a thriving community of fellow woodworkers. Don’t let uncertainty hold you back. Navigate the complexities of woodworking with confidence and precision. Discover the resources you need at conduct.edu.vn to ensure safety, accuracy, and ethical practices in every project. For more information, contact us at 100 Ethics Plaza, Guideline City, CA 90210, United States, or via Whatsapp at +1 (707) 555-1234.