Making precise and clean cuts with a circular saw can be challenging without the right tools and techniques. This is where a circular saw guide rail comes in handy. How to make a circular saw guide rail? This guide, brought to you by CONDUCT.EDU.VN, offers a detailed, step-by-step approach to building your own guide rail, ensuring accuracy and safety in your woodworking projects. Discover woodworking tips and diy projects for precise cuts.

1. Understanding the Need for a Circular Saw Guide Rail

A circular saw guide rail, also known as a track saw guide, is a crucial accessory for any woodworking enthusiast or professional. It provides a straight edge for your circular saw to follow, resulting in cleaner, more accurate cuts. Before diving into how to make a circular saw guide rail, let’s understand why it’s so essential.

1.1. Accuracy and Precision

Achieving straight cuts with a circular saw can be difficult, especially when working with large sheets of material. A guide rail eliminates this problem by providing a consistent reference point for the saw to follow. This results in precise cuts, reducing the risk of errors and wasted material.

1.2. Safety

Using a guide rail enhances safety by keeping the saw aligned and preventing it from wandering off course. This reduces the likelihood of kickback and other accidents, making the woodworking process safer and more controlled. Adhering to safety protocols and maintaining a safe environment is paramount. Further safety guidelines and resources can be found at CONDUCT.EDU.VN, located at 100 Ethics Plaza, Guideline City, CA 90210, United States, or by contacting +1 (707) 555-1234.

1.3. Efficiency

With a guide rail, you can make cuts more quickly and efficiently. You don’t need to spend time measuring and marking lines repeatedly. Simply align the guide rail with your desired cut line, clamp it in place, and run the saw along the rail.

1.4. Portability

Unlike a table saw, which is stationary and requires a dedicated workspace, a circular saw with a guide rail is portable. This makes it ideal for on-site jobs or workshops with limited space.

2. Identifying Your Needs

Before you learn how to make a circular saw guide rail, assess your specific woodworking needs. Consider the following:

2.1. Project Types

What types of projects will you be working on? If you frequently cut large sheets of plywood or other sheet goods, a longer guide rail is essential. For smaller projects, a shorter rail may suffice.

2.2. Saw Compatibility

Ensure that your circular saw is compatible with the guide rail design you choose. Consider the saw’s base size and shape, as well as any unique features that may affect its ability to glide smoothly along the rail.

2.3. Workspace

How much space do you have in your workshop? If space is limited, a compact guide rail design may be preferable.

3. Choosing the Right Materials

The materials you select for your circular saw guide rail will impact its durability, accuracy, and overall performance. Here’s a breakdown of common material options:

3.1. Plywood

Plywood is a popular choice for guide rails due to its stability, affordability, and availability. Choose a high-quality plywood with a smooth, flat surface for best results. Baltic birch plywood is an excellent option due to its void-free construction and dimensional stability.

3.2. Medium-Density Fiberboard (MDF)

MDF is another suitable material for guide rails. It’s denser than plywood and has a smoother surface, making it ideal for creating a precise cutting edge. However, MDF is more susceptible to moisture damage, so it’s essential to seal it properly.

3.3. Aluminum

Aluminum is a durable and lightweight material that’s often used for professional-grade guide rails. It’s more expensive than plywood or MDF, but it offers superior accuracy and longevity.

3.4. Steel

Steel is the most durable material option, but it’s also the heaviest and most expensive. Steel guide rails are typically used in industrial settings where precision and durability are paramount.

4. Essential Tools for the Build

To successfully learn how to make a circular saw guide rail, you’ll need the following tools:

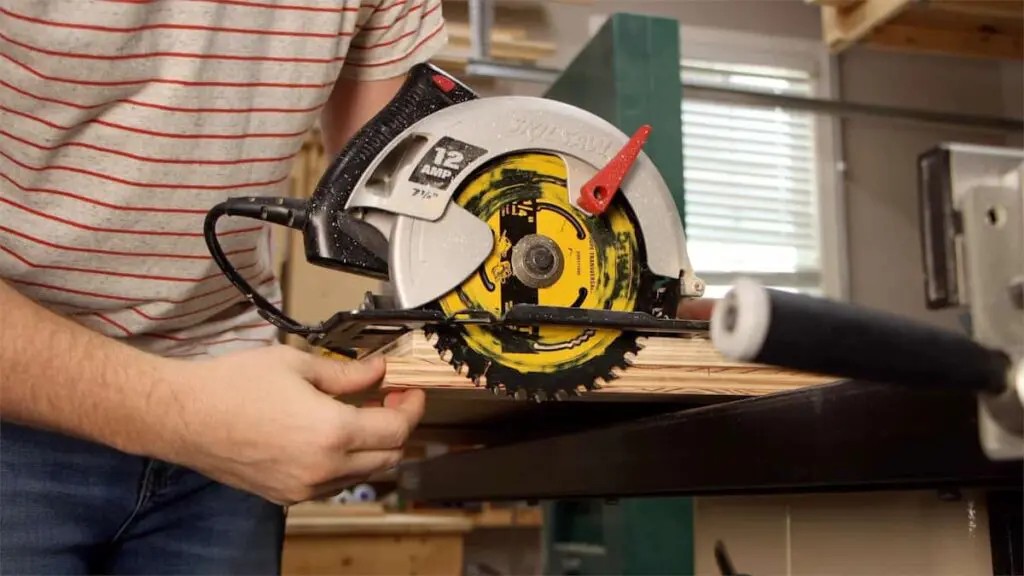

- Circular Saw: Of course, you’ll need the saw you intend to use with the guide rail.

- Table Saw or Track Saw: For making straight, accurate cuts on the guide rail components.

- Measuring Tools: A tape measure, ruler, and square are essential for accurate measurements.

- Clamps: To hold the guide rail components securely in place during assembly.

- Drill/Driver: For drilling pilot holes and driving screws.

- Screws: Choose screws that are appropriate for the material you’re using.

- Wood Glue: For bonding the guide rail components together.

- Safety Glasses: To protect your eyes from debris.

- Hearing Protection: To reduce noise exposure.

5. Step-by-Step Guide: How to Make a Circular Saw Guide Rail

Now, let’s dive into the step-by-step process of how to make a circular saw guide rail.

5.1. Cutting the Base

- Measure and Cut: Cut a piece of plywood or MDF to the desired length and width for the base of your guide rail. A common length is 4 to 8 feet, and the width should be at least 12 inches to provide ample support for the saw and clamps.

- Ensure Straightness: Use a table saw or track saw to ensure that the edges of the base are perfectly straight and parallel. This is crucial for accurate cuts.

5.2. Attaching the Guide Strip

- Cut the Guide Strip: Cut a strip of plywood or MDF that is approximately 2 to 3 inches wide and the same length as the base. This strip will serve as the guide for the circular saw.

- Apply Glue: Apply a thin, even layer of wood glue to the edge of the base where the guide strip will be attached.

- Position the Guide Strip: Carefully position the guide strip on the glued edge of the base, ensuring that it is flush with the edge and perfectly straight.

- Clamp in Place: Use clamps to hold the guide strip securely in place while the glue dries. Ensure that the clamps are evenly spaced and apply consistent pressure.

5.3. Adding Support Strips (Optional)

- Cut Support Strips: Cut two or more strips of plywood or MDF that are approximately 1 to 2 inches wide and the same length as the base.

- Position Support Strips: Position the support strips parallel to the guide strip, spacing them evenly across the width of the base.

- Apply Glue and Clamp: Apply glue to the bottom of the support strips and clamp them in place. These strips will provide additional support and rigidity to the guide rail.

5.4. Creating the Zero-Clearance Edge

- Prepare the Saw: Place your circular saw on the base, with the blade positioned next to the guide strip.

- Adjust Blade Depth: Adjust the blade depth so that it slightly protrudes through the bottom of the base.

- Make the Cut: Carefully run the saw along the guide strip, cutting away a narrow strip of the base. This creates a zero-clearance edge that perfectly matches the kerf of your saw blade.

- Ensure Smooth Movement: Ensure smooth, fluid motion and consistent pressure against the guide strip. This is critical for achieving a clean, accurate cut.

5.5. Sanding and Finishing

- Sand the Edges: Use sandpaper to smooth any rough edges or imperfections on the guide rail.

- Apply Finish: Apply a clear coat of polyurethane or another protective finish to seal the wood and prevent moisture damage.

6. Alternative Methods for Building a Guide Rail

While the above method provides a robust and accurate guide rail, there are alternative approaches you can consider.

6.1. Using Metal Tracks

Some woodworkers prefer to use metal tracks as the guide rail. These tracks are typically made of aluminum or steel and offer exceptional accuracy and durability.

- Purchase Metal Tracks: Purchase metal tracks from a woodworking supply store or online retailer.

- Attach Tracks to Base: Attach the metal tracks to a plywood or MDF base using screws or adhesive.

- Ensure Compatibility: Ensure that your circular saw is compatible with the metal tracks. You may need to purchase a special adapter or mounting plate.

6.2. Utilizing Clamping Straight Edges

Clamping straight edges are commercially available and can be used as a temporary guide rail.

- Purchase Clamping Straight Edge: Buy a clamping straight edge of the desired length.

- Position and Clamp: Position the clamping straight edge along your cut line and clamp it securely in place.

- Run Saw Along Edge: Run your circular saw along the edge of the clamping straight edge, keeping the saw base flush against the edge.

7. Tips for Accurate Cuts

Even with a well-built guide rail, there are several tips to keep in mind to ensure accurate cuts:

7.1. Measure Accurately

Double-check your measurements before making any cuts. Use a sharp pencil and a precise measuring tool.

7.2. Clamp Securely

Ensure that the guide rail is securely clamped in place before running the saw. Use multiple clamps to prevent the rail from shifting during the cut.

7.3. Maintain Consistent Pressure

Apply consistent pressure to the saw as you guide it along the rail. Avoid pushing too hard or allowing the saw to wander.

7.4. Use a Sharp Blade

A sharp blade is essential for clean, accurate cuts. Replace your blade regularly or sharpen it as needed.

7.5. Practice Makes Perfect

Practice using the guide rail on scrap material before tackling your final project. This will help you get a feel for the tool and develop your technique.

8. Common Mistakes to Avoid

When learning how to make a circular saw guide rail, be aware of these common mistakes:

- Using Warped Materials: Avoid using warped or twisted plywood or MDF, as this will compromise the accuracy of your guide rail.

- Inadequate Clamping: Insufficient clamping can cause the guide rail to shift during the cut, resulting in inaccurate results.

- Rushing the Process: Take your time and pay attention to detail. Rushing can lead to mistakes and poor-quality cuts.

- Ignoring Safety Precautions: Always wear safety glasses and hearing protection when working with power tools.

- Neglecting Maintenance: Keep your guide rail clean and free of debris. Regularly inspect it for damage and make any necessary repairs.

9. Enhancing Your Guide Rail

Consider these enhancements to improve the functionality and versatility of your guide rail:

9.1. Adding T-Tracks

Install T-tracks along the base of the guide rail to allow for the attachment of accessories such as clamps, stops, and feather boards.

9.2. Incorporating a Dust Collection Port

Add a dust collection port to the guide rail to capture sawdust and keep your workspace clean.

9.3. Creating Adjustable Stops

Install adjustable stops along the guide rail to make repeatable cuts quickly and accurately.

10. Real-World Applications

A circular saw guide rail is invaluable for a wide range of woodworking projects:

- Cutting Plywood: Easily cut large sheets of plywood to size for cabinets, shelving, and other projects.

- Making Dadoes and Rabbets: Create precise dadoes and rabbets for joinery.

- Trimming Doors and Windows: Trim doors and windows to fit openings accurately.

- Building Furniture: Construct furniture with clean, straight lines and precise angles.

- Installing Flooring: Cut flooring planks to size quickly and accurately.

11. Safety Considerations

Safety is paramount when working with power tools. Adhere to these safety guidelines when using your circular saw guide rail:

- Wear Safety Glasses: Always wear safety glasses to protect your eyes from flying debris.

- Use Hearing Protection: Wear hearing protection to reduce noise exposure.

- Keep Hands Clear: Keep your hands clear of the blade at all times.

- Secure Workpiece: Ensure that your workpiece is securely clamped or supported.

- Unplug Saw When Adjusting: Always unplug the saw before making any adjustments or changing the blade.

- Inspect for Damage: Before each use, inspect the guide rail and saw for any damage.

- Follow Manufacturer’s Instructions: Always follow the manufacturer’s instructions for both the saw and the guide rail.

12. Troubleshooting Common Issues

Even with careful planning and execution, you may encounter issues when using your circular saw guide rail. Here are some common problems and their solutions:

- Inaccurate Cuts: Check for warped materials, loose clamps, or a dull blade.

- Saw Wandering: Ensure that the saw base is flush against the guide rail and that you are applying consistent pressure.

- Splintering: Use a sharp blade and score the cut line before making the final cut.

- Guide Rail Slipping: Use non-slip pads or apply additional clamping pressure.

- Dust Buildup: Regularly clean the guide rail and saw to prevent dust buildup.

13. Maintenance and Care

Proper maintenance and care will extend the life of your circular saw guide rail and ensure its accuracy.

- Clean Regularly: Clean the guide rail after each use to remove sawdust and debris.

- Store Properly: Store the guide rail in a dry, safe place to prevent damage.

- Inspect for Damage: Regularly inspect the guide rail for any signs of damage, such as cracks, warping, or loose components.

- Tighten Fasteners: Periodically tighten any screws or bolts that may have loosened over time.

- Apply Lubricant: Apply a dry lubricant to the saw base and guide rail to ensure smooth movement.

14. The Ethical Considerations of Woodworking

While woodworking is a rewarding hobby and profession, it’s essential to consider the ethical implications of your material choices and practices.

14.1. Sustainable Wood Sourcing

Choose wood from sustainable sources to minimize your environmental impact. Look for wood that is certified by the Forest Stewardship Council (FSC) or other reputable organizations.

14.2. Reducing Waste

Minimize waste by carefully planning your cuts and using scrap material for smaller projects.

14.3. Safe Disposal of Waste

Dispose of sawdust, wood scraps, and finishing materials properly. Avoid burning treated wood, as it can release harmful chemicals into the atmosphere.

14.4. Respecting the Environment

Be mindful of the impact your woodworking activities have on the environment. Avoid working in sensitive areas and take steps to minimize noise and dust pollution.

More information on ethical practices can be obtained from CONDUCT.EDU.VN, ensuring that all projects align with responsible and sustainable guidelines.

15. Commercially Available Options

While building your own guide rail is a rewarding project, commercially available options offer convenience and precision. Brands like Festool, Makita, and DeWalt offer high-quality track saw systems.

15.1. Festool Track Saw System

Festool is renowned for its precision and quality. Their track saw system includes a guide rail, saw, and accessories that integrate seamlessly for exceptional performance.

15.2. Makita Track Saw

Makita offers a range of track saws with features like variable speed control and soft start. Their guide rails are durable and accurate.

15.3. DeWalt Track Saw

DeWalt track saws are known for their power and durability. Their guide rails are designed to withstand heavy use.

16. Understanding Google E-E-A-T and YMYL

In the context of online content, Google’s E-E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) and YMYL (Your Money or Your Life) guidelines are crucial. E-E-A-T evaluates the quality of content, while YMYL applies to topics that could potentially impact a person’s health, financial stability, safety, or well-being.

16.1. Applying E-E-A-T to Woodworking Content

To adhere to E-E-A-T guidelines, woodworking content should be:

- Experienced-Based: Share your personal experiences and insights.

- Expertly Written: Demonstrate in-depth knowledge of woodworking techniques and tools.

- Authoritative: Cite reputable sources and demonstrate your credibility in the field.

- Trustworthy: Provide accurate and reliable information and be transparent about your sources.

16.2. YMYL and Woodworking

While woodworking may not always fall directly under YMYL, safety-related content does. Ensure that all safety advice is accurate, up-to-date, and based on reliable sources.

17. Optimizing Your Content for Google Discovery

To increase the visibility of your woodworking content on Google Discovery, follow these best practices:

17.1. Use High-Quality Images and Videos

Visually appealing content is more likely to be featured on Google Discovery. Use high-resolution images and videos that showcase your projects and techniques.

17.2. Write Compelling Headlines

Craft headlines that are attention-grabbing and accurately reflect the content of your article.

17.3. Focus on User Intent

Create content that addresses the specific needs and interests of your target audience.

17.4. Optimize for Mobile

Ensure that your website is mobile-friendly, as a significant portion of Google Discovery traffic comes from mobile devices.

17.5. Promote Your Content

Share your content on social media and other platforms to increase its reach.

18. Advanced Techniques

For those looking to enhance their woodworking skills further, consider these advanced techniques:

18.1. Inlays and Veneers

Learn how to create decorative inlays and apply veneers to add elegance and visual interest to your projects.

18.2. Wood Turning

Explore the art of wood turning, using a lathe to create beautiful bowls, spindles, and other decorative items.

18.3. Carving

Develop your carving skills to create intricate designs and textures on wood surfaces.

19. Frequently Asked Questions (FAQ)

Q1: What is the ideal length for a circular saw guide rail?

A: The ideal length depends on your project needs. A 4-foot guide rail is suitable for smaller projects, while an 8-foot rail is better for larger sheets of plywood.

Q2: Can I use a circular saw guide rail with any circular saw?

A: Most circular saws are compatible with guide rails, but it’s essential to check the saw’s base size and shape.

Q3: What’s the best material for a circular saw guide rail?

A: Plywood and MDF are popular choices for their stability and affordability. Aluminum and steel offer superior durability and accuracy.

Q4: How do I ensure accurate cuts with a circular saw guide rail?

A: Measure accurately, clamp securely, maintain consistent pressure, and use a sharp blade.

Q5: How do I prevent splintering when cutting with a circular saw?

A: Use a sharp blade and score the cut line before making the final cut.

Q6: Can I make angled cuts with a circular saw guide rail?

A: Yes, you can make angled cuts by adjusting the angle of the saw blade.

Q7: How do I maintain my circular saw guide rail?

A: Clean it regularly, store it properly, inspect it for damage, and tighten any loose fasteners.

Q8: What are the safety precautions to consider when using a circular saw guide rail?

A: Wear safety glasses and hearing protection, keep hands clear of the blade, and ensure the workpiece is secure.

Q9: Are there commercially available circular saw guide rails?

A: Yes, brands like Festool, Makita, and DeWalt offer high-quality track saw systems.

Q10: How do I choose a sustainable wood source for my woodworking projects?

A: Look for wood that is certified by the Forest Stewardship Council (FSC) or other reputable organizations.

20. Conclusion

Mastering how to make a circular saw guide rail empowers you to achieve precise, safe, and efficient cuts in your woodworking projects. By following this comprehensive guide, you can create your own custom guide rail or choose a commercially available option that suits your needs. Remember to prioritize safety, sustainability, and ethical considerations in all your woodworking endeavors. For more information and guidance, visit CONDUCT.EDU.VN, located at 100 Ethics Plaza, Guideline City, CA 90210, United States, or contact +1 (707) 555-1234. Let CONDUCT.EDU.VN be your trusted partner in navigating the world of ethical conduct and woodworking excellence.

If you’re finding it challenging to implement best practices, CONDUCT.EDU.VN offers services that provide detailed, easy-to-understand information on ethical conduct and woodworking techniques. Let us help you build a more ethical and efficient workspace. Visit our website at conduct.edu.vn for more details.