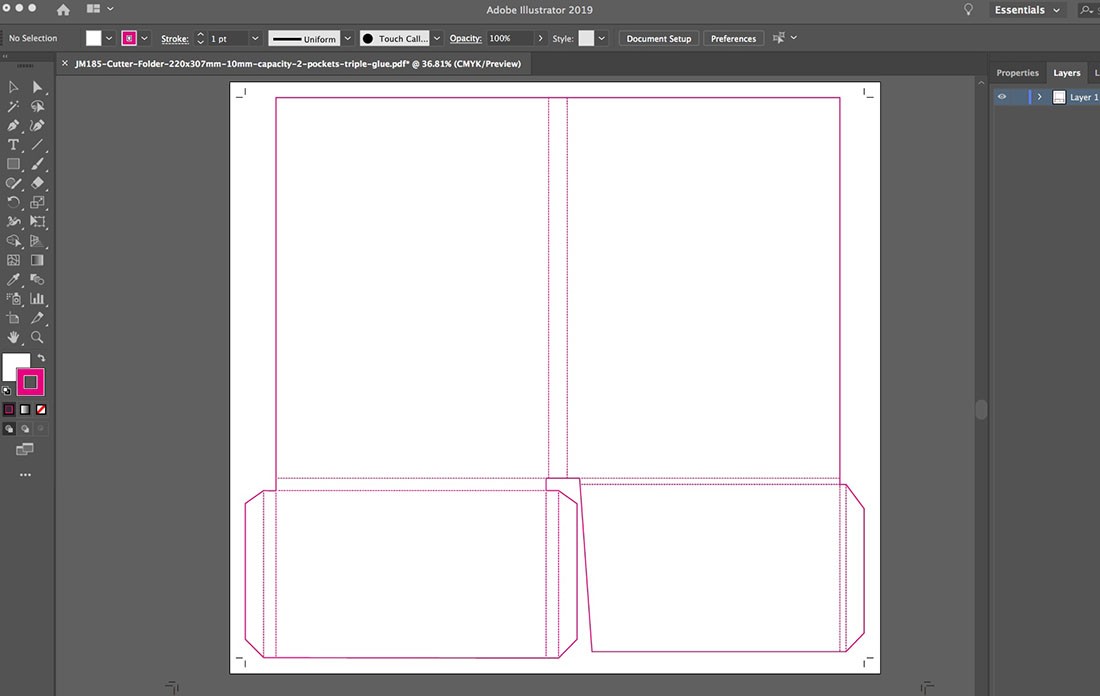

A cutter guide is a crucial element in the printing and die-cutting process. It’s essentially a key line drawing, often created as an additional layer on top of the artwork. This guide precisely indicates where the cutting and creasing lines will be located once the design is printed and die-cut.

Cutter guides are essential for producing both simple and complex printed materials, ranging from business cards with rounded corners and swing tags to sophisticated door hangers, professional presentation folders, point-of-sale (POS) displays, and specialized packaging solutions.

Why is a Cutter Guide Necessary?

A cutter guide is indispensable for ensuring that the correct tooling, also known as a cutting block or die, is created to accurately die-cut your product according to the intended design. Without a precise cutter guide, the final product may not match the desired shape and dimensions, leading to errors and waste.

Production Time for Cutting Blocks

When planning a die-cut project, it’s crucial to consider the time and cost involved. Creating bespoke tooling can take several days, so factor this into your project timeline. The complexity of the design significantly impacts the manufacturing time of the cutting block.

Cost Considerations for Cutting Blocks

The cost of a cutting block can vary significantly, depending on the size, shape, and complexity. Discuss your project with your printer beforehand to understand the potential expenses. Intricate and custom shapes typically incur higher tooling costs.

The cutting tool’s cost is usually integrated into the overall printing project expenses. For smaller production runs, the cost per copy can be higher due to the initial setup costs associated with creating the custom tooling. Larger volumes often benefit from economies of scale, reducing the per-unit cost.

How to Reduce Cutter Costs

To avoid the cost of creating a custom cutter, consider using pre-existing cutter guides. Many printers, including Print Worx, offer a range of established cutter guides that can save you both time and money. By designing your artwork to fit these existing guidelines, you eliminate the need for a new cutting tool.

Printers often maintain a library of standard cutter guides for common products such as capacity or non-capacity folders, allowing clients to leverage these resources for cost-effective solutions.

In summary, understanding what a cutter guide is, why it’s needed, and how it impacts the overall printing process is crucial for anyone involved in design, print production, or packaging.